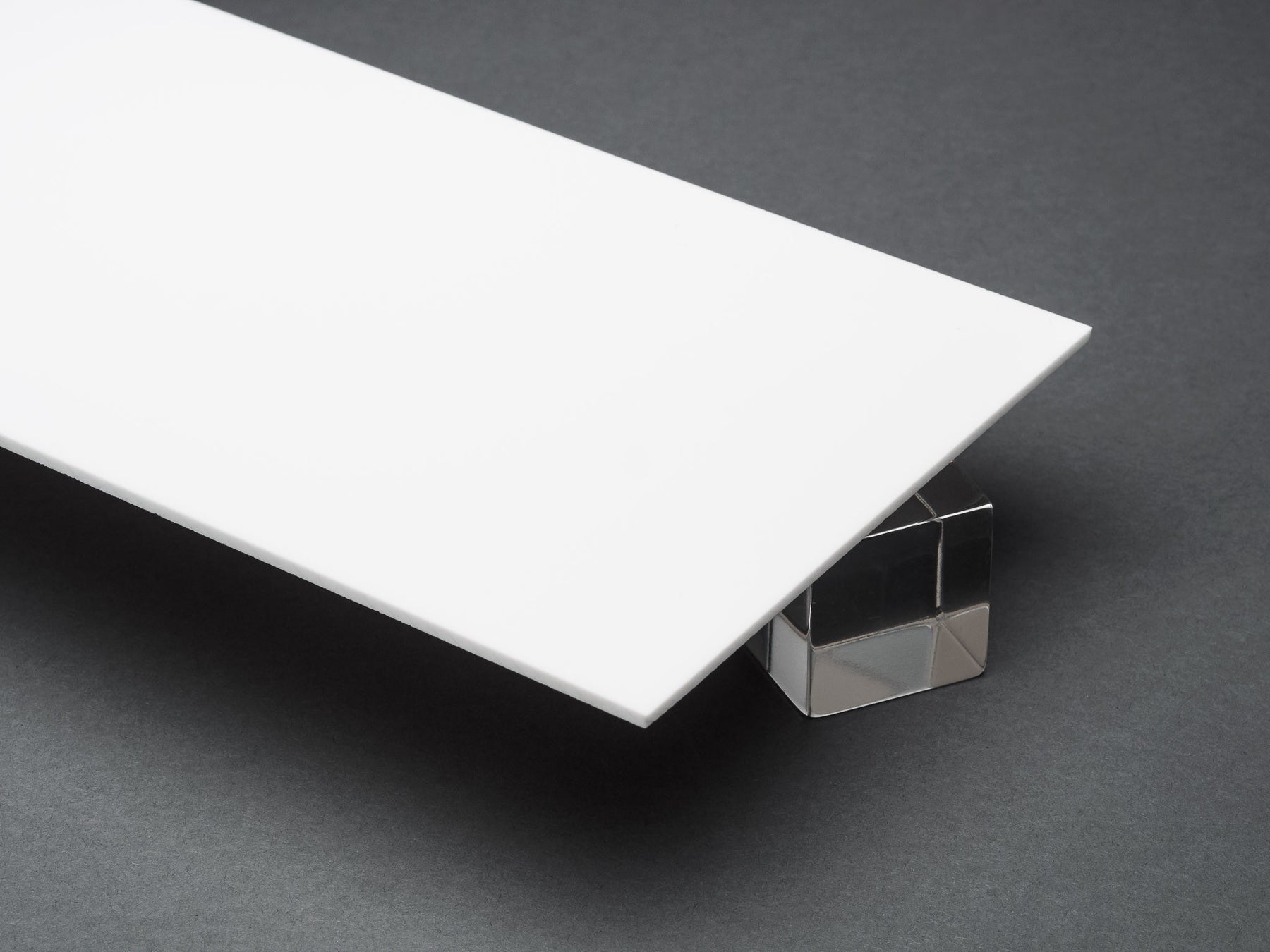

Unveiling the Excellence of P-95 Acrylic: Properties, Applications, and Advantages

In the realm of high-performance plastics, P-95 acrylic stands out as a versatile and reliable material. Known for its exceptional optical clarity, weather resistance, and durability, P-95 acrylic finds applications across diverse industries, from aerospace and automotive to architecture and signage. This article delves into the properties, applications, advantages, and considerations surrounding P-95 acrylic, providing a comprehensive understanding of this remarkable polymer.

Understanding P-95 Acrylic: A Deep Dive

P-95 acrylic, a specific grade of acrylic polymer, exhibits superior properties compared to standard acrylics. Its formulation is optimized for enhanced performance, particularly in demanding environments. To truly appreciate P-95 acrylic, it’s crucial to understand its composition and the characteristics that set it apart.

Chemical Composition and Manufacturing

Acrylic polymers, generally, are derived from acrylic acid or methacrylic acid. P-95 acrylic is often a polymethyl methacrylate (PMMA) based material, modified to achieve specific performance enhancements. The manufacturing process involves polymerization, where monomers (small repeating units) link together to form long chains, creating the acrylic polymer. The specific process and additives used in the production of P-95 acrylic significantly influence its final properties.

Key Properties of P-95 Acrylic

- Optical Clarity: P-95 acrylic boasts exceptional light transmission, making it ideal for applications requiring high transparency and minimal distortion.

- Weather Resistance: Unlike some other polymers, P-95 acrylic exhibits excellent resistance to UV radiation, moisture, and temperature fluctuations, ensuring long-term performance in outdoor environments.

- Impact Resistance: While not as impact-resistant as polycarbonate, P-95 acrylic offers good impact strength, making it suitable for applications where moderate impact resistance is required.

- Chemical Resistance: P-95 acrylic demonstrates good resistance to a range of chemicals, including acids, alkalis, and solvents. However, it’s important to consult chemical resistance charts for specific chemicals and concentrations.

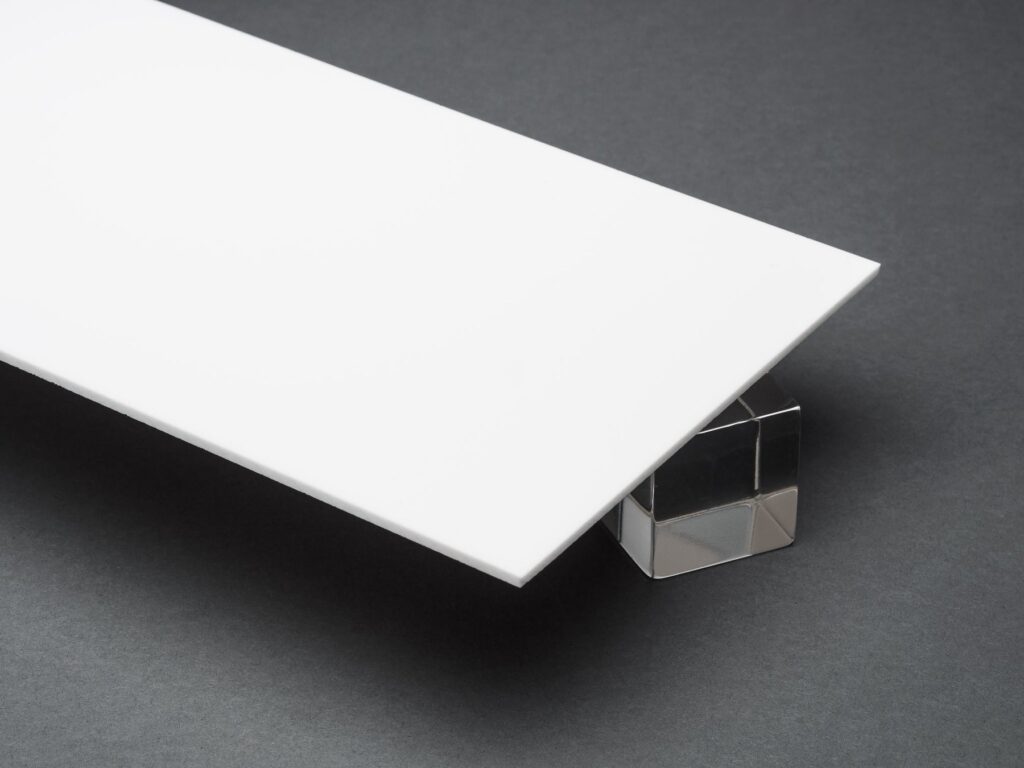

- Machinability: P-95 acrylic can be easily machined, cut, drilled, and thermoformed, facilitating its fabrication into various shapes and sizes.

- Lightweight: Compared to glass, P-95 acrylic is significantly lighter, reducing structural load and simplifying handling.

Applications of P-95 Acrylic Across Industries

The unique combination of properties exhibited by P-95 acrylic makes it a versatile material for a wide array of applications. Let’s explore some key industries where P-95 acrylic shines.

Aerospace

In the aerospace industry, P-95 acrylic is utilized for aircraft windows, canopies, and interior components. Its optical clarity, weather resistance, and lightweight nature make it an ideal choice for these demanding applications. The ability of P-95 acrylic to withstand the harsh conditions of flight, including UV radiation and temperature variations, is critical for ensuring safety and performance.

Automotive

P-95 acrylic finds applications in automotive lighting, instrument panels, and exterior trim. Its high light transmission and resistance to yellowing make it suitable for headlights and taillights, while its durability and weather resistance ensure long-term performance in automotive environments. [See also: Automotive Acrylic Applications]

Architecture

In architecture, P-95 acrylic is used for skylights, windows, and signage. Its optical clarity, weather resistance, and design flexibility allow architects to create visually appealing and energy-efficient structures. P-95 acrylic can also be used in decorative panels and partitions, adding a touch of elegance to interior spaces.

Signage

P-95 acrylic is a popular choice for signage due to its excellent optical clarity, weather resistance, and ease of fabrication. It can be easily cut, shaped, and printed on, allowing for the creation of custom signs with vibrant colors and sharp details. The UV resistance of P-95 acrylic ensures that signs remain legible and attractive for years to come.

Medical Devices

Certain grades of P-95 acrylic are used in medical devices, such as diagnostic equipment and surgical instruments. Its biocompatibility and sterilizability make it suitable for these sensitive applications. P-95 acrylic can also be used in protective shields and enclosures for medical equipment.

Displays and Exhibits

The exceptional clarity of P-95 acrylic makes it an ideal material for displays and exhibits. It allows for unobstructed viewing of products and artifacts, while also providing protection from dust and damage. P-95 acrylic can be easily fabricated into custom display cases and stands.

Advantages of Using P-95 Acrylic

Choosing P-95 acrylic over other materials offers several distinct advantages. Here’s a summary of the key benefits:

- Superior Optical Clarity: Provides exceptional light transmission and minimal distortion.

- Excellent Weather Resistance: Withstands UV radiation, moisture, and temperature fluctuations.

- Good Impact Resistance: Offers adequate impact strength for many applications.

- Chemical Resistance: Resists a range of chemicals, ensuring long-term performance.

- Easy Machinability: Can be easily cut, drilled, and thermoformed.

- Lightweight: Reduces structural load and simplifies handling compared to glass.

- Design Flexibility: Can be molded into various shapes and sizes.

- Long Service Life: Offers excellent durability and resistance to degradation.

Considerations When Working with P-95 Acrylic

While P-95 acrylic offers numerous advantages, it’s important to be aware of certain considerations when working with this material.

Scratch Resistance

P-95 acrylic is susceptible to scratching, although specialized coatings can improve its scratch resistance. Handle with care and avoid abrasive cleaning materials.

Chemical Compatibility

While P-95 acrylic offers good chemical resistance, it’s crucial to consult chemical resistance charts to ensure compatibility with specific chemicals. Certain solvents can cause damage or discoloration.

Thermal Expansion

P-95 acrylic has a relatively high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. Account for this expansion when designing and installing P-95 acrylic components.

Cost

P-95 acrylic can be more expensive than standard acrylics or other plastics. However, its superior performance and long service life can justify the higher cost in many applications.

The Future of P-95 Acrylic

As technology advances, the demand for high-performance plastics like P-95 acrylic is expected to grow. Ongoing research and development efforts are focused on further enhancing the properties of P-95 acrylic, such as improving its scratch resistance, impact strength, and chemical resistance. We can anticipate seeing even wider adoption of P-95 acrylic across various industries in the years to come. [See also: Advanced Acrylic Materials]

Conclusion: Embracing the Versatility of P-95 Acrylic

P-95 acrylic is a remarkable material that offers a unique combination of properties, making it suitable for a wide range of applications. Its optical clarity, weather resistance, durability, and ease of fabrication make it a preferred choice for industries such as aerospace, automotive, architecture, and signage. By understanding the properties, advantages, and considerations surrounding P-95 acrylic, engineers, designers, and manufacturers can leverage its full potential to create innovative and high-performing products. The future of P-95 acrylic looks bright, with ongoing advancements promising even greater performance and versatility in the years to come. Choosing P-95 acrylic often leads to a more durable, reliable, and visually appealing final product, making it a worthwhile investment for many applications.