Unveiling the Clarity: A Comprehensive Guide to Acrylic Clear

In the world of materials science, few substances offer the unique combination of transparency, durability, and versatility found in acrylic clear. From everyday household items to sophisticated industrial applications, acrylic clear has become an indispensable component. This article delves into the properties, applications, advantages, and considerations associated with acrylic clear, providing a comprehensive understanding of this remarkable material.

What is Acrylic Clear?

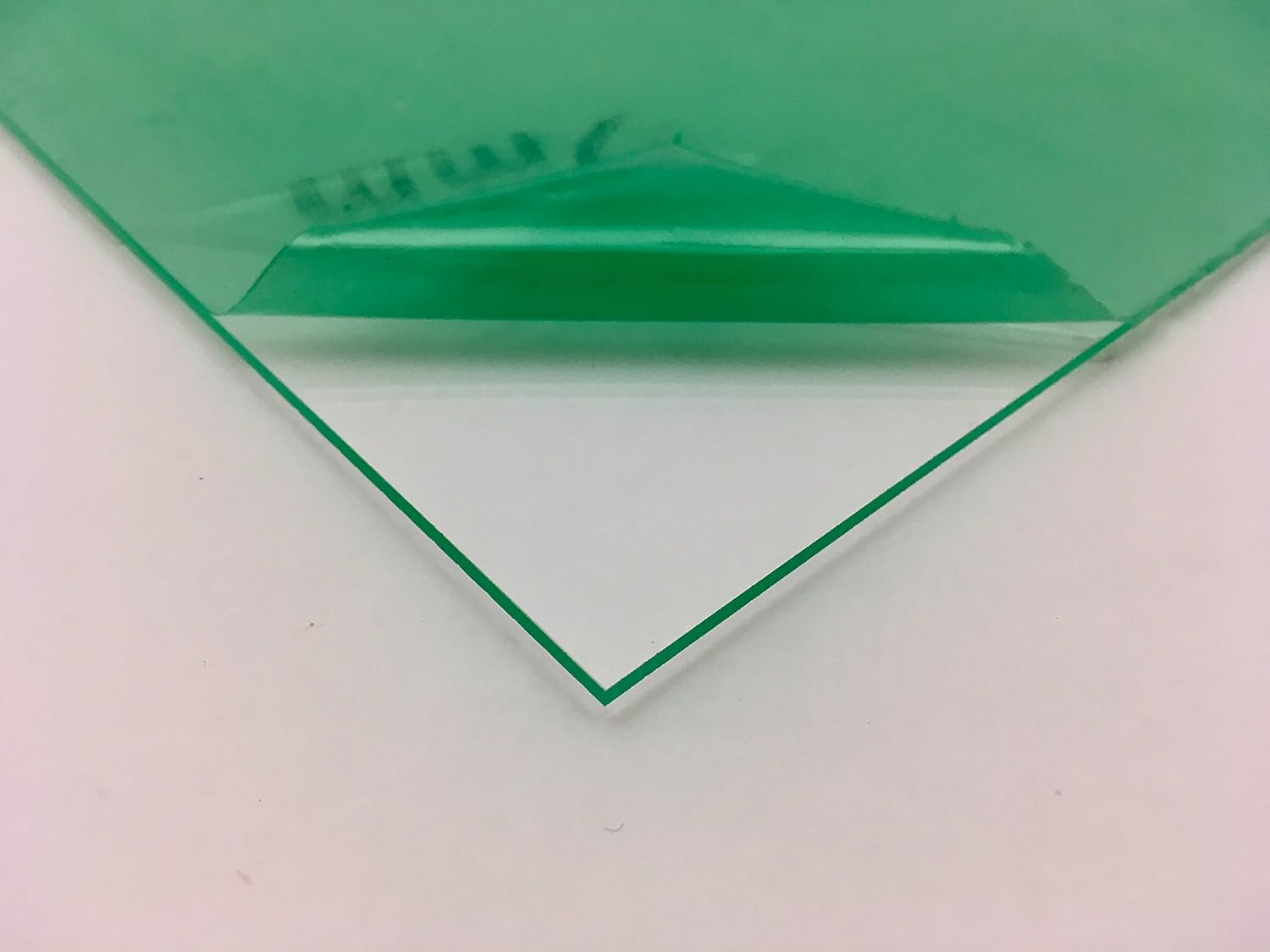

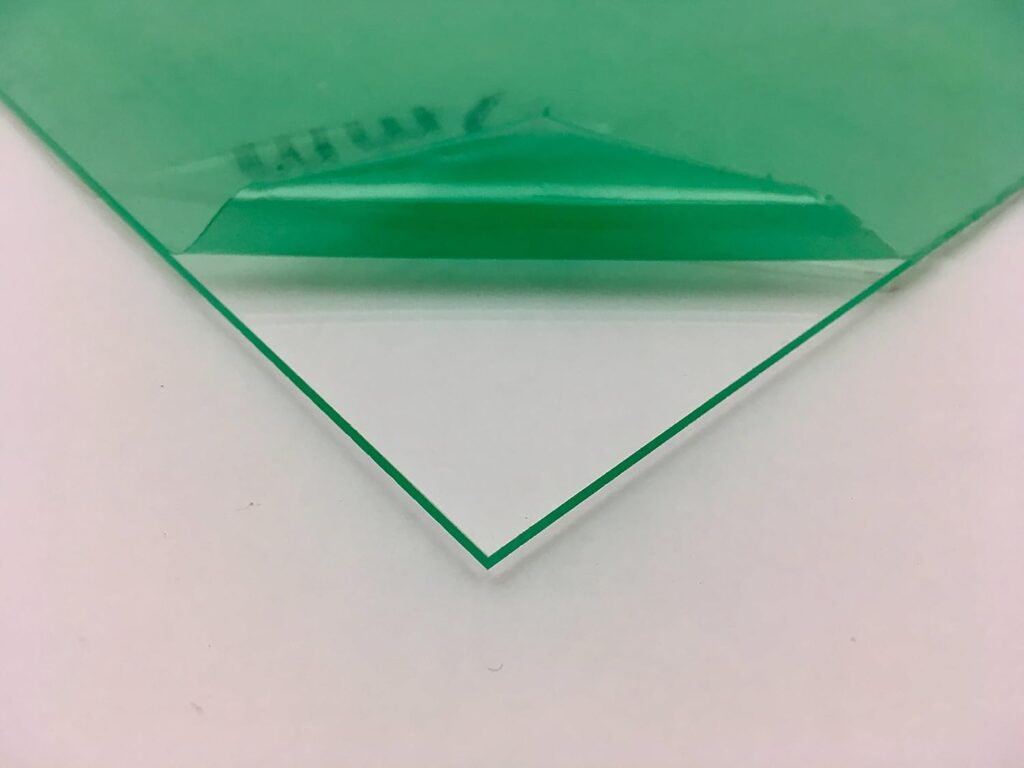

Acrylic clear, also known as polymethyl methacrylate (PMMA), is a synthetic polymer derived from methyl methacrylate. It’s a thermoplastic, meaning it softens when heated and hardens when cooled, allowing it to be molded and reshaped multiple times without significant degradation. This property makes it highly adaptable for various manufacturing processes.

Unlike glass, acrylic clear is shatter-resistant and significantly lighter, making it a safer and more manageable alternative in many applications. Its exceptional optical clarity, often exceeding that of glass, allows for excellent light transmission, making it ideal for applications where visibility is crucial.

Key Properties of Acrylic Clear

- Transparency: Offers exceptional light transmission, often exceeding 90%.

- Impact Resistance: More resistant to shattering than glass.

- Lightweight: Significantly lighter than glass, reducing structural load.

- Weather Resistance: Resistant to UV degradation, making it suitable for outdoor applications.

- Chemical Resistance: Resistant to many chemicals, although susceptible to some solvents.

- Moldability: Can be easily molded and shaped into various forms.

- Optical Clarity: Minimal distortion, providing a clear view.

Applications of Acrylic Clear

The versatility of acrylic clear lends itself to a wide array of applications across diverse industries. Here are some notable examples:

Architectural Uses

Acrylic clear sheets are widely used in architecture for windows, skylights, and safety glazing. Its impact resistance and weather resistance make it a superior choice over glass in areas prone to storms or vandalism. Furthermore, its lightweight nature simplifies installation and reduces structural support requirements.

Signage and Displays

In the signage industry, acrylic clear is a staple material. Its clarity and ease of fabrication make it ideal for creating illuminated signs, display cases, and point-of-sale displays. The material can be easily cut, engraved, and printed on, allowing for custom designs and branding.

Automotive Industry

Acrylic clear is used in automotive applications for tail lights, headlight lenses, and interior components. Its durability and resistance to yellowing from UV exposure ensure long-lasting performance and aesthetic appeal. The ability to mold it into complex shapes is also a significant advantage.

Medical Devices

The biocompatibility and clarity of acrylic clear make it suitable for certain medical devices, such as diagnostic equipment and protective shields. Its resistance to sterilization processes is also an important factor in medical applications.

Aquariums and Tanks

Large aquariums and tanks often utilize thick acrylic clear panels due to their superior strength and clarity compared to glass. The material can withstand significant water pressure and provides a clear, undistorted view of aquatic life.

Protective Barriers and Shields

In various settings, including retail stores and security checkpoints, acrylic clear is used to create protective barriers and shields. Its impact resistance offers protection against physical threats, while its transparency allows for clear communication and visibility.

Art and Design

Artists and designers utilize acrylic clear for sculptures, display cases, and decorative elements. Its ability to be shaped and illuminated allows for creative expression and unique visual effects. The material’s clarity also enhances the presentation of artwork and collectibles. [See also: Acrylic Painting Techniques]

Advantages of Using Acrylic Clear

Choosing acrylic clear over other materials offers several distinct advantages:

- Superior Clarity: Provides exceptional light transmission and minimal distortion.

- High Impact Resistance: Less prone to shattering compared to glass.

- Lightweight: Reduces structural load and simplifies installation.

- Weather Resistance: Suitable for outdoor applications due to UV resistance.

- Versatile: Can be easily molded, cut, and fabricated into various shapes.

- Cost-Effective: Often a more affordable option than glass, especially for large panels.

Considerations When Using Acrylic Clear

While acrylic clear offers numerous benefits, it’s essential to consider certain factors when selecting and using the material:

- Scratch Resistance: More prone to scratching than glass, requiring careful handling and cleaning.

- Chemical Sensitivity: Can be damaged by certain solvents and chemicals.

- Thermal Expansion: Has a higher coefficient of thermal expansion than glass, requiring proper allowance in designs.

- Cost: While often cost-effective, specialized grades or thicknesses can be more expensive.

Types of Acrylic Clear

Acrylic clear comes in various forms, each suited for specific applications:

Cast Acrylic

Cast acrylic clear is produced by pouring liquid acrylic between two sheets of glass or metal and allowing it to cure. This process results in a higher quality sheet with superior optical clarity and resistance to distortion. Cast acrylic is often preferred for applications requiring precision and high aesthetic standards.

Extruded Acrylic

Extruded acrylic clear is manufactured by forcing molten acrylic through a die. This process is more cost-effective than casting but can result in slightly lower optical clarity and dimensional stability. Extruded acrylic is commonly used for general-purpose applications where high precision is not critical.

Acrylic Clear Rods and Tubes

In addition to sheets, acrylic clear is also available in the form of rods and tubes. These are used for various applications, including lighting fixtures, decorative elements, and fluid handling systems. [See also: LED Lighting Design]

Working with Acrylic Clear

Fabricating acrylic clear requires specific tools and techniques to achieve optimal results. Here are some essential considerations:

Cutting

Acrylic clear can be cut using various methods, including saw cutting, laser cutting, and routing. Saw cutting requires a fine-toothed blade and slow feed rate to prevent chipping and cracking. Laser cutting provides precise cuts and intricate designs. Routing is suitable for creating complex shapes and edges.

Drilling

When drilling acrylic clear, it’s essential to use a slow drill speed and apply light pressure to prevent cracking. Special drill bits designed for plastics are recommended to achieve clean and accurate holes.

Bonding

Acrylic clear can be bonded using various adhesives, including solvent cements and acrylic adhesives. Solvent cements dissolve the acrylic surfaces and fuse them together, creating a strong and seamless bond. Acrylic adhesives provide a strong and durable bond without dissolving the acrylic.

Cleaning

Cleaning acrylic clear requires gentle methods to avoid scratching the surface. Use a soft cloth and mild soap and water solution. Avoid using abrasive cleaners or solvents, as these can damage the acrylic. Special acrylic cleaners are available for removing stubborn stains and fingerprints.

The Future of Acrylic Clear

The future of acrylic clear looks promising, with ongoing research and development focused on enhancing its properties and expanding its applications. Innovations in materials science are leading to the development of new grades of acrylic clear with improved scratch resistance, UV protection, and impact strength.

Furthermore, advancements in manufacturing techniques are enabling the production of more complex and intricate acrylic clear components. The integration of smart technologies, such as embedded sensors and displays, is also opening up new possibilities for acrylic clear in various industries.

Conclusion

Acrylic clear stands as a testament to the power of materials science, offering a unique combination of clarity, durability, and versatility. Its widespread applications across various industries underscore its importance in modern technology and design. By understanding its properties, advantages, and considerations, professionals and consumers alike can make informed decisions when selecting and utilizing this remarkable material. The future innovations promise even greater potential for acrylic clear, solidifying its role as a key component in shaping the world around us. Its adaptability ensures that acrylic clear will remain a relevant and valuable material for years to come.