Unlocking the Potential of Dual Lock Strips: A Comprehensive Guide

In today’s fast-paced world, the need for reliable and versatile fastening solutions has never been greater. Enter dual lock strips, a game-changing technology that offers a robust and adaptable alternative to traditional fasteners like screws, bolts, and adhesives. These strips, characterized by their interlocking mushroom-shaped stems, provide a secure and reclosable bond, making them ideal for a wide range of applications. This comprehensive guide will delve into the mechanics, benefits, applications, and best practices of using dual lock strips, ensuring you’re equipped with the knowledge to leverage their full potential.

Understanding Dual Lock Technology

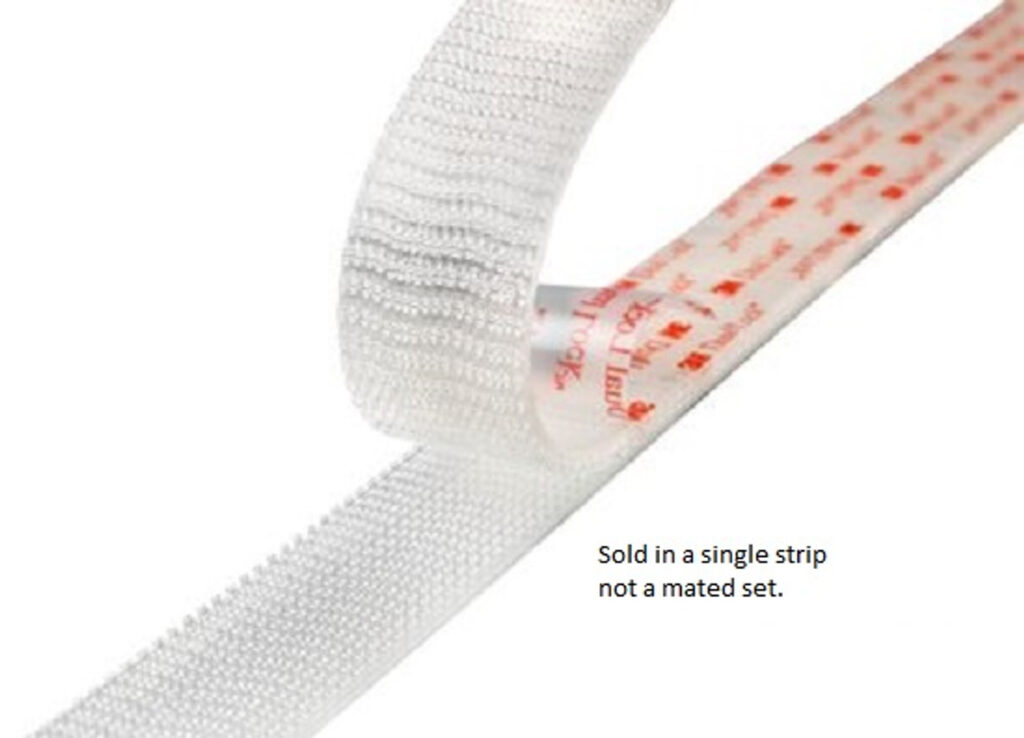

Dual lock strips, often referred to as reclosable fasteners, are engineered with precision. Unlike hook-and-loop fasteners, dual lock strips feature hundreds or even thousands of interlocking mushroom-shaped stems per square inch. These stems snap together when pressed, creating a strong and audible “snap” that indicates a secure connection. The density and design of these stems directly influence the holding power of the strip. Higher stem density translates to a stronger bond, capable of withstanding significant shear and tensile forces. The material used in manufacturing these strips, typically polypropylene or similar polymers, contributes to their durability and resistance to environmental factors like moisture and temperature variations.

The science behind the grip is surprisingly simple yet effective. When the two surfaces are pressed together, the mushroom heads deflect and interlock, creating a secure mechanical bond. This bond is strong enough to hold substantial weight, yet it can be easily disengaged by simply peeling the strips apart. This reclosable nature makes dual lock strips a superior option for applications requiring repeated access or adjustments.

Key Features and Benefits

- Strong and Reliable Bond: Provides a secure and dependable connection, often stronger than traditional hook-and-loop fasteners.

- Reclosable and Adjustable: Allows for repeated opening and closing without compromising the bond’s integrity. This is a key advantage over permanent adhesives.

- Vibration Resistant: The interlocking stems provide excellent resistance to vibrations, making them suitable for applications in moving vehicles or machinery.

- Clean and Aesthetically Pleasing: Eliminates the need for unsightly screws or bolts, creating a cleaner and more professional appearance.

- Easy to Use: Simple application process that requires minimal tools or expertise.

- Versatile Applications: Suitable for a wide range of materials, including plastics, metals, glass, and painted surfaces.

- Durable and Long-Lasting: Resistant to environmental factors and wear, ensuring a long service life.

Applications Across Industries

The versatility of dual lock strips has led to their adoption in numerous industries. Their ability to provide a strong, reclosable bond makes them invaluable in various applications.

Automotive Industry

In the automotive sector, dual lock strips are used for attaching interior panels, trim, and even exterior components. Their vibration resistance is particularly beneficial in this environment. They provide a secure hold while allowing for easy removal for maintenance or repairs. For example, attaching headliners, door panels, and dashboard components are common applications. The clean finish they provide is also a significant advantage, enhancing the overall aesthetic of the vehicle’s interior.

Electronics

Electronics manufacturers utilize dual lock strips for securing access panels, mounting components inside enclosures, and even attaching devices to surfaces. Their non-conductive properties make them safe for use around sensitive electronic components. The reclosable nature of the strips is crucial for applications requiring frequent access for testing, repairs, or upgrades. Consider the ease of accessing internal components of a computer tower or securing a sensor to a piece of equipment.

Signage and Displays

The signage and display industry benefits from the ease of use and clean appearance of dual lock strips. They are ideal for mounting signs, posters, and displays on walls or other surfaces without the need for drilling or screws. This is particularly useful in retail environments where displays need to be changed frequently. The ability to reposition or remove the display without damaging the surface is a significant advantage.

Medical Devices

In the medical field, dual lock strips are used in various applications, including securing medical equipment to carts or walls, attaching sensors to patients, and assembling medical devices. Their strength, reliability, and ease of cleaning make them suitable for the demanding requirements of the healthcare industry. The ability to withstand repeated sterilization cycles is also a crucial factor in this sector.

Aerospace

The aerospace industry demands high-performance materials and fasteners. Dual lock strips meet these requirements by providing a strong, lightweight, and vibration-resistant solution for attaching interior panels, seating, and other components within aircraft cabins. Their ability to withstand extreme temperatures and pressures is critical in this environment. Furthermore, the reclosable nature of the strips facilitates easy access for maintenance and inspections.

Choosing the Right Dual Lock Strip

Selecting the appropriate dual lock strips for your application is crucial to ensure optimal performance. Several factors should be considered:

- Holding Strength: Determine the weight and forces the strip needs to withstand. Different dual lock strips offer varying levels of holding strength, measured in pounds per square inch (PSI).

- Material Compatibility: Ensure the strip is compatible with the materials being joined. Some strips are designed for specific surfaces, such as plastics, metals, or painted surfaces.

- Temperature Range: Consider the temperature range the application will be exposed to. Some strips are designed for high-temperature environments, while others are better suited for moderate temperatures.

- Environmental Conditions: Evaluate the environmental conditions the strip will be exposed to, such as moisture, UV radiation, or chemicals. Choose a strip that is resistant to these factors.

- Thickness: The thickness of the strip can affect its performance and appearance. Choose a thickness that is appropriate for the application.

- Adhesive Type: Dual lock strips are available with various adhesive backings, including acrylic, rubber, and foam adhesives. Select an adhesive that provides a strong and durable bond to the target surface.

Application Best Practices

Proper application is essential to maximize the performance and longevity of dual lock strips. Follow these best practices:

- Surface Preparation: Clean the surfaces to be joined thoroughly with a suitable solvent to remove any dirt, grease, or contaminants. Ensure the surfaces are dry before applying the strips.

- Adhesive Application: Apply the dual lock strips to one surface first, pressing firmly to ensure good adhesion. Allow the adhesive to cure for the recommended time before joining the two surfaces.

- Alignment: Carefully align the two surfaces before pressing them together. Once the strips are engaged, it can be difficult to reposition them.

- Pressure: Apply firm and even pressure to both surfaces to ensure the interlocking stems are fully engaged. Listen for the audible “snap” that indicates a secure connection.

- Cure Time: Allow the adhesive to fully cure before subjecting the joint to any significant loads. The recommended cure time varies depending on the adhesive type and environmental conditions.

- Testing: Before relying on the joint in a critical application, test its strength and reliability. This can be done by applying a gradually increasing load to the joint and monitoring its performance.

The Future of Fastening: Dual Lock Strips

Dual lock strips represent a significant advancement in fastening technology. Their strength, versatility, and reclosable nature make them an ideal solution for a wide range of applications across various industries. As technology continues to evolve, we can expect to see further innovations in dual lock strip design and materials, leading to even greater performance and versatility. The future of fastening is undoubtedly being shaped by the innovative capabilities of dual lock strips. [See also: Different Types of Fasteners] Their ability to provide a secure, reliable, and reclosable bond makes them an indispensable tool for engineers, designers, and manufacturers alike. The ongoing development and refinement of dual lock strips promise to unlock even more possibilities in the years to come. They truly offer a superior alternative to traditional methods. The adaptability and robustness of these strips are unmatched. Considering the benefits of using dual lock strips, it’s clear why they’re becoming a staple in various industries. The innovative design and reliable performance of dual lock strips make them a top choice for many applications. When selecting a fastening solution, remember the advantages that dual lock strips provide. The durability and ease of use of dual lock strips contribute to their widespread adoption. For a secure and reclosable bond, dual lock strips are an excellent option. Always consider the specific requirements of your application when choosing dual lock strips. The right choice of dual lock strips can significantly improve the efficiency and reliability of your project.