The Ultimate Guide to Tool Labels: Organization and Efficiency

In any workshop, garage, or even a well-organized toolbox, the key to efficiency and safety often lies in the details. One of the most overlooked, yet profoundly impactful, details is the strategic use of labels for tools. Properly labeling your tools not only enhances organization but also saves time, reduces frustration, and minimizes the risk of using the wrong tool for the job. This guide explores the myriad benefits of tool labeling, the best methods for creating durable and effective labels, and practical tips for implementing a comprehensive tool labeling system.

Why Use Labels for Tools?

The advantages of implementing a robust system of labels for tools are numerous. Let’s delve into some of the most compelling reasons:

- Enhanced Organization: A designated spot for each tool, clearly marked with a label, ensures that tools are returned to their proper place after use. This keeps your workspace tidy and organized.

- Time Savings: Quickly identifying the tool you need without rummaging through a disorganized drawer or toolbox saves valuable time, especially on urgent projects.

- Reduced Frustration: Knowing exactly where each tool belongs minimizes the frustration of searching for misplaced items.

- Increased Efficiency: When tools are readily accessible, work flows more smoothly, leading to increased overall efficiency.

- Improved Safety: Using the correct tool for the job is crucial for safety. Clear labels for tools help prevent accidents caused by using inappropriate or damaged tools.

- Inventory Management: A well-labeled tool collection makes it easier to keep track of what you have and identify missing items, preventing unnecessary purchases.

Choosing the Right Labeling Method

Selecting the appropriate labeling method depends on factors such as the type of tools, the environment in which they are used, and your personal preferences. Here are some popular options:

Engraved Labels

Engraved labels offer a permanent and professional solution, particularly suitable for metal tools. Engraving machines can etch text or symbols directly onto the tool’s surface, creating a durable and weather-resistant label for tools.

Embossed Labels

Embossed labels are created using a handheld embossing tool that punches raised characters onto a plastic or metal strip. They are relatively inexpensive and easy to apply, making them a popular choice for home workshops.

Printed Labels

Printed labels offer the most flexibility in terms of design and information. You can create custom labels using a computer and printer, incorporating text, symbols, and even barcodes. High-quality label printers and durable label materials are essential for ensuring longevity.

Handwritten Labels

While not as durable or professional-looking as other options, handwritten labels can be a quick and easy solution for temporary or low-stakes situations. Use a permanent marker designed for industrial use to ensure the writing doesn’t fade or smudge easily. Consider applying clear tape over the label for added protection.

Materials for Durable Labels

The longevity of your labels for tools depends heavily on the materials used. Here are some of the most durable and reliable options:

- Vinyl Labels: Vinyl is a popular choice for its durability and resistance to water, oil, and chemicals. Vinyl labels are available in a variety of colors and sizes, and they can be printed with thermal transfer printers for long-lasting results.

- Polyester Labels: Polyester labels offer even greater durability than vinyl, with excellent resistance to abrasion, temperature extremes, and UV exposure. They are ideal for tools that are frequently used or exposed to harsh conditions.

- Metal Labels: Metal labels, such as aluminum or stainless steel, are the most durable option, providing exceptional resistance to wear and tear. They are often used in industrial settings where tools are subjected to heavy use and harsh environments.

- Laminated Labels: Laminating any label protects it from scratches, moisture, and fading. You can purchase pre-laminated labels or laminate your own using a laminating machine.

Creating an Effective Tool Labeling System

Implementing a successful system of labels for tools requires careful planning and execution. Here are some key steps to consider:

- Assess Your Needs: Before you start labeling, take inventory of your tools and identify the areas where labeling would be most beneficial. Consider the types of tools you have, the environment in which they are used, and the information you want to include on each label.

- Choose a Consistent Labeling Scheme: Develop a consistent labeling scheme that is easy to understand and follow. This might involve assigning numbers, letters, or colors to different tool categories or individual tools.

- Design Your Labels: Create clear and concise labels that are easy to read. Use a legible font size and choose colors that contrast well with the background. Include essential information such as the tool’s name, size, or function.

- Apply the Labels: Carefully apply the labels to the tools, ensuring that they are securely attached and positioned in a visible location. Clean the tool surface before applying the label to ensure proper adhesion.

- Maintain Your System: Regularly inspect your labels and replace any that are damaged or faded. Update your labeling system as needed to reflect changes in your tool collection or organizational needs.

Tips for Long-Lasting Tool Labels

To maximize the lifespan of your labels for tools, consider these tips:

- Clean the Surface: Before applying a label, thoroughly clean the tool’s surface with isopropyl alcohol to remove any dirt, grease, or oil.

- Use a Primer: For difficult-to-adhere surfaces, apply a primer designed to improve label adhesion.

- Protect the Edges: Round the corners of your labels to prevent them from peeling up over time.

- Apply Clear Tape: Cover your labels with clear packing tape or heat shrink tubing for added protection against abrasion and moisture.

- Choose the Right Adhesive: Select labels with a strong adhesive that is suitable for the tool’s material and the environment in which it is used.

Examples of Tool Labeling Applications

Toolbox Organization

Labeling each compartment or drawer in your toolbox helps you quickly locate the tool you need without having to sift through a jumbled mess. You can also label the outside of the toolbox to indicate its contents.

Workshop Storage

Labeling shelves, bins, and drawers in your workshop makes it easy to store and retrieve tools and supplies. Use large, easy-to-read labels to identify the contents of each storage container.

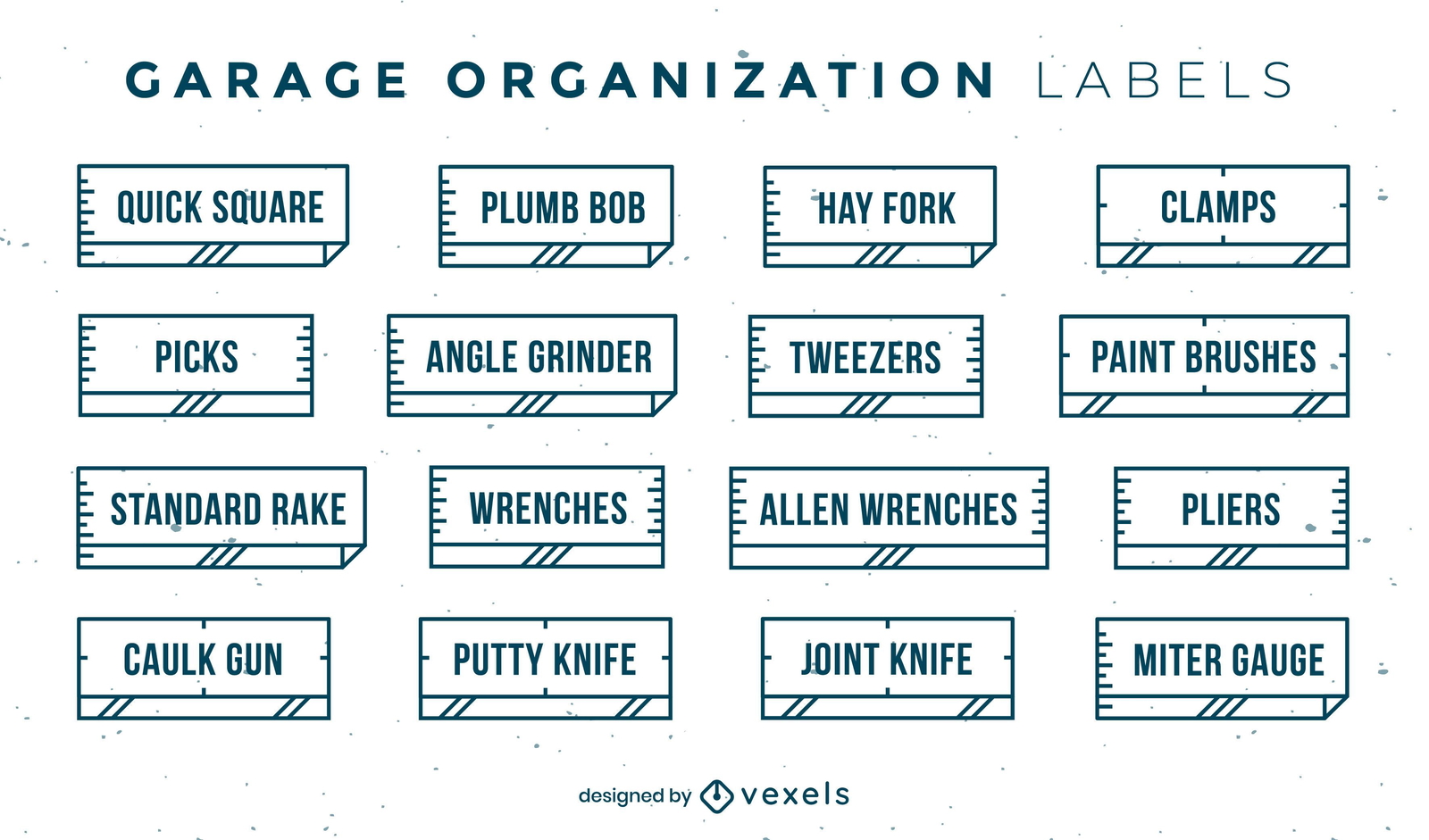

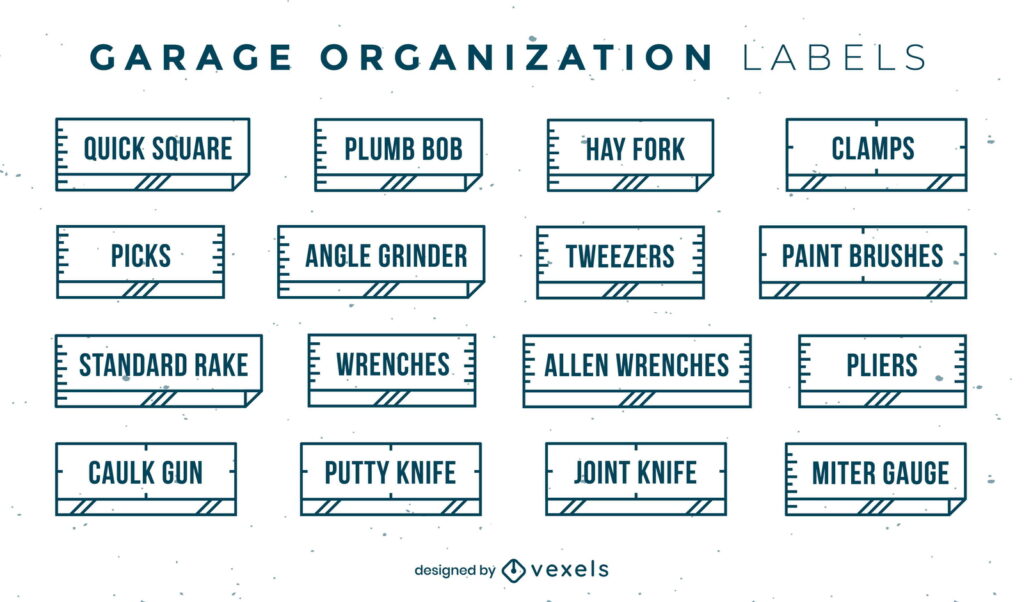

Garage Organization

In a garage, labels for tools can be used to organize everything from garden tools to power tools. Labeling storage racks, hooks, and shelves helps you keep your garage tidy and efficient.

Professional Settings

In professional settings, tool labeling is essential for maintaining accountability and preventing loss. Each tool can be assigned a unique identification number and labeled accordingly. This system helps track tool usage, schedule maintenance, and prevent theft.

The Future of Tool Labeling

As technology advances, the future of labels for tools is likely to involve more sophisticated solutions such as RFID tags and QR codes. These technologies allow for real-time tracking of tools, automated inventory management, and enhanced security. [See also: Smart Tool Management Systems] Imagine a system where you can scan a QR code on a tool and instantly access its maintenance history, user manual, and safety information.

Conclusion

Implementing a comprehensive system of labels for tools is a worthwhile investment that can significantly improve organization, efficiency, and safety in any workspace. By choosing the right labeling method, using durable materials, and following best practices, you can create a tool labeling system that will last for years to come. Whether you are a DIY enthusiast, a professional tradesperson, or simply someone who values a well-organized workspace, the benefits of tool labeling are undeniable. So, take the time to label your tools today and experience the difference it makes.