The Ultimate Guide to Labels for Tools: Organization and Efficiency

In any workshop, garage, or even a simple toolbox, organization is key. And at the heart of effective organization lies a simple yet powerful tool: labels for tools. More than just stickers, these labels for tools are the unsung heroes that bring order to chaos, save time, and ultimately, boost productivity. This comprehensive guide will delve into the various aspects of using labels for tools, from the types available to best practices for application and maintenance.

Why Use Labels for Tools?

The benefits of using labels for tools extend far beyond simple aesthetics. Consider these advantages:

- Improved Organization: Clearly labeled tools are easier to find and return to their designated places.

- Increased Efficiency: Time spent searching for the right tool is time wasted. Labels for tools eliminate guesswork and streamline workflows.

- Reduced Tool Loss: When tools have assigned locations, they are less likely to be misplaced or lost.

- Enhanced Safety: Knowing where tools belong and what they are used for can prevent accidents and injuries.

- Professional Appearance: A well-organized and labeled workspace conveys a sense of professionalism and attention to detail.

Types of Labels for Tools

Choosing the right type of labels for tools depends on the specific application, environment, and budget. Here’s a breakdown of the most common options:

Printed Labels

These are created using a label maker or printed from a computer onto adhesive label sheets. They offer a high degree of customization and are suitable for a wide range of applications.

- Pros: Highly customizable, readily available, cost-effective for small quantities.

- Cons: Can be less durable than other options, susceptible to fading or damage from solvents.

Engraved Labels

Engraved labels for tools are created by etching text or graphics onto a durable material such as metal or plastic. They are highly resistant to wear and tear and are ideal for harsh environments.

- Pros: Extremely durable, resistant to chemicals and abrasion, long-lasting.

- Cons: More expensive than printed labels, require specialized equipment for creation.

Embossed Labels

Embossed labels for tools are created by raising the text or graphics above the surface of the label. This provides a tactile and visually distinctive effect.

- Pros: Durable, easy to read, adds a professional touch.

- Cons: Limited customization options, can be more expensive than printed labels.

Color-Coded Labels

Color-coded labels for tools use different colors to categorize tools based on type, function, or ownership. This can be a particularly effective way to organize large tool collections.

- Pros: Easy to visually identify tools, simplifies organization, can be used to differentiate tools by user.

- Cons: Requires a consistent color-coding system, can be less effective for people with color blindness.

QR Code Labels

QR code labels for tools can be scanned with a smartphone or tablet to access additional information about the tool, such as its manual, maintenance schedule, or location history. This is a great option for advanced tool management.

- Pros: Provides access to detailed information, facilitates tool tracking, can be integrated with inventory management systems.

- Cons: Requires a smartphone or tablet for scanning, depends on the availability of a digital database.

Choosing the Right Material for Your Labels

The material of your labels for tools is just as important as the type of label. Consider the following factors when selecting a material:

- Durability: How resistant is the material to wear and tear, abrasion, and impact?

- Water Resistance: Will the label withstand exposure to water or moisture?

- Chemical Resistance: Will the label be damaged by solvents, oils, or other chemicals?

- Temperature Resistance: Can the label withstand extreme temperatures without peeling or fading?

- Adhesive Strength: How well does the label adhere to the tool surface?

Common materials for labels for tools include:

- Vinyl: Durable, water-resistant, and available in a variety of colors and finishes.

- Polyester: Highly resistant to chemicals and abrasion, ideal for harsh environments.

- Metal: Extremely durable and long-lasting, suitable for engraved or embossed labels.

- Paper: Cost-effective for temporary or indoor applications, but less durable than other options.

Applying Labels for Tools: Best Practices

Even the best labels for tools won’t be effective if they are not applied properly. Follow these best practices to ensure that your labels stay in place and remain legible:

- Clean the Surface: Before applying a label, thoroughly clean the tool surface with a degreaser or isopropyl alcohol to remove any dirt, grease, or oil.

- Dry the Surface: Make sure the surface is completely dry before applying the label.

- Apply Even Pressure: Use a squeegee or your fingers to apply even pressure to the label, working from the center outwards to avoid air bubbles.

- Overlap the Edges: If possible, overlap the edges of the label to provide extra protection against peeling.

- Protect with Clear Coating: For added durability, consider applying a clear coat of polyurethane or epoxy over the label.

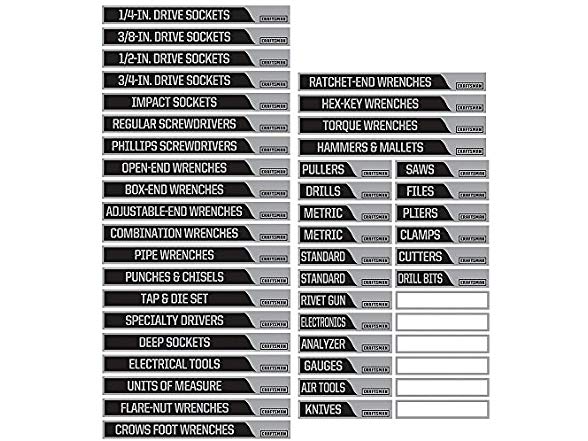

Labeling Specific Types of Tools

The best approach to labeling will vary depending on the type of tool. Here are some tips for labeling specific categories:

Hand Tools

For hand tools like screwdrivers, wrenches, and pliers, use small, durable labels that won’t interfere with grip or functionality. Consider wrapping the label around the handle or applying it to a flat surface.

Power Tools

For power tools like drills, saws, and sanders, use larger, more visible labels that clearly identify the tool and its function. Be sure to position the label so that it doesn’t obstruct any moving parts or vents. Clearly labeled power tools improve safety and efficiency. [See also: Power Tool Safety Tips]

Measuring Tools

For measuring tools like tape measures, rulers, and calipers, use precise, easy-to-read labels that won’t distort the measurements. Consider using engraved or embossed labels for long-term accuracy.

Specialty Tools

For specialty tools like automotive tools, plumbing tools, or electrical tools, use color-coded labels to differentiate them by function or application. This can help prevent confusion and ensure that the right tool is used for the job.

Maintaining Your Labels

To ensure that your labels for tools remain legible and effective, it’s important to maintain them properly. Here are some tips:

- Regularly Inspect: Check your labels regularly for signs of wear and tear, such as peeling, fading, or damage.

- Clean as Needed: Clean your labels with a mild detergent and water to remove any dirt or grime.

- Replace Damaged Labels: Replace any damaged or illegible labels immediately to maintain a clear and organized system.

- Consider Protective Coatings: Applying a clear coat of polyurethane or epoxy can help protect your labels from damage and extend their lifespan.

The Future of Labels for Tools

The world of labels for tools is constantly evolving, with new technologies and materials emerging all the time. Expect to see even more sophisticated labeling solutions in the future, such as:

- Smart Labels: Labels that can communicate with inventory management systems and provide real-time data on tool location and usage.

- Self-Healing Labels: Labels that can automatically repair minor scratches and abrasions.

- Biodegradable Labels: Environmentally friendly labels made from sustainable materials.

Conclusion

Labels for tools are an essential component of any well-organized workspace. By choosing the right type of label, material, and application method, you can create a system that saves time, reduces tool loss, and enhances safety. So, take the time to label your tools today and experience the benefits of a truly organized and efficient workspace. The investment in quality labels for tools will pay off handsomely in the long run, making your work easier, faster, and more enjoyable.