The Ultimate Guide to Black Double Sided Mounting Tape: Strength, Uses, and Best Practices

In the world of adhesives, black double sided mounting tape stands out as a versatile and reliable solution for a wide range of applications. From DIY projects to industrial assembly, its strong adhesive properties and discreet appearance make it a go-to choice for professionals and hobbyists alike. This comprehensive guide will delve into the specifics of black double sided mounting tape, exploring its composition, advantages, applications, and best practices for optimal use.

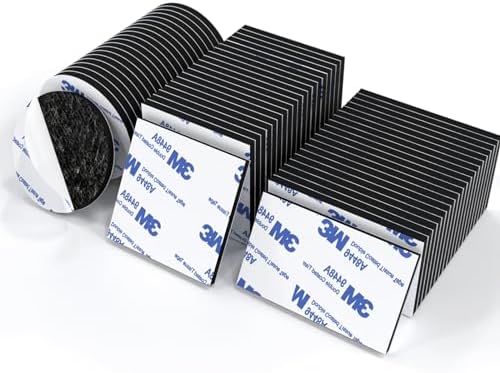

What is Black Double Sided Mounting Tape?

Black double sided mounting tape is an adhesive tape coated with adhesive on both sides, allowing it to bond two surfaces together. The ‘black’ refers to the color of the adhesive or the backing material, often chosen for aesthetic reasons or to blend seamlessly with dark-colored surfaces. This type of tape is designed to provide a strong, permanent bond, making it suitable for mounting objects without the need for screws, nails, or liquid adhesives.

Composition and Types

Black double sided mounting tape typically consists of three main components:

- Adhesive: The adhesive layer is the key to the tape’s bonding capabilities. Common adhesive types include acrylic, rubber, and silicone, each offering different levels of strength, temperature resistance, and adhesion to various materials. Acrylic adhesives are known for their durability and resistance to UV light and chemicals, while rubber adhesives provide excellent initial tack and adhesion to irregular surfaces.

- Carrier or Backing: The carrier is the material that supports the adhesive layers. Common carriers include foam, film, and tissue. Foam carriers, often made from polyethylene or polyurethane, provide cushioning and gap-filling properties, making them ideal for uneven surfaces. Film carriers, such as polyester or polypropylene, offer high strength and dimensional stability.

- Release Liner: The release liner is a protective layer that covers the adhesive until the tape is ready for use. It is typically made of paper or film coated with a release agent, allowing for easy removal without leaving residue on the adhesive.

Advantages of Using Black Double Sided Mounting Tape

Black double sided mounting tape offers several advantages over traditional fastening methods:

- Strong Bond: High-quality black double sided mounting tape can provide a strong, permanent bond, capable of supporting significant weight. The strength of the bond depends on the type of adhesive, the surface materials, and the application technique.

- Clean and Discreet: Unlike screws or nails, black double sided mounting tape leaves no visible holes or marks on the surfaces being joined. The black color blends seamlessly with dark-colored materials, providing a clean and professional appearance.

- Easy to Use: Applying black double sided mounting tape is a simple and straightforward process. It requires no special tools or skills, making it accessible to both professionals and DIY enthusiasts.

- Versatile: Black double sided mounting tape can be used on a wide range of materials, including metal, plastic, glass, wood, and composites. This versatility makes it suitable for numerous applications.

- Vibration Damping: Foam-backed black double sided mounting tape can dampen vibrations and reduce noise, making it ideal for applications where noise reduction is important.

- Gap Filling: Foam carriers can also fill gaps between surfaces, creating a more uniform and aesthetically pleasing appearance.

- Weather Resistance: Certain types of black double sided mounting tape are designed to withstand extreme temperatures, humidity, and UV exposure, making them suitable for outdoor applications.

Applications of Black Double Sided Mounting Tape

The versatility of black double sided mounting tape makes it suitable for a wide array of applications across various industries:

Automotive Industry

In the automotive industry, black double sided mounting tape is used for attaching emblems, trim, and interior components. Its strong bond and resistance to temperature fluctuations make it ideal for these demanding applications. [See also: Automotive Adhesive Solutions]

Construction and Building

In construction, black double sided mounting tape is used for mounting signs, mirrors, and decorative panels. Its ability to bond to a variety of surfaces, including concrete, drywall, and metal, makes it a valuable tool for contractors and builders.

Electronics

Electronics manufacturers use black double sided mounting tape for securing components, wires, and displays. Its non-conductive properties and ability to provide a strong bond without damaging sensitive electronics make it an essential material in this industry.

Signage and Displays

Black double sided mounting tape is widely used in the signage industry for mounting signs, posters, and displays. Its clean appearance and strong bond ensure that signs remain securely in place, even in challenging environments.

DIY and Home Improvement

For DIY enthusiasts and homeowners, black double sided mounting tape is a versatile tool for a variety of projects. It can be used for mounting picture frames, organizing cables, and attaching decorative items to walls. Its ease of use and clean appearance make it a popular choice for home improvement projects.

Industrial Applications

In industrial settings, black double sided mounting tape is used for a wide range of applications, including bonding metal panels, attaching insulation, and assembling components. Its strong bond and resistance to harsh environments make it suitable for demanding industrial applications.

Best Practices for Using Black Double Sided Mounting Tape

To achieve the best results with black double sided mounting tape, follow these best practices:

Surface Preparation

Proper surface preparation is crucial for achieving a strong and lasting bond. Before applying the tape, ensure that the surfaces are clean, dry, and free from dust, oil, and other contaminants. Use a suitable cleaner, such as isopropyl alcohol, to remove any residue. For porous surfaces, such as wood or concrete, consider using a primer to improve adhesion.

Application Technique

Apply the black double sided mounting tape evenly and firmly to one surface. Remove the release liner and carefully align the second surface. Press firmly to ensure good contact between the tape and both surfaces. Avoid trapping air bubbles between the tape and the surfaces.

Curing Time

Allow sufficient curing time for the adhesive to fully bond. The curing time will vary depending on the type of adhesive and the environmental conditions. Refer to the manufacturer’s recommendations for specific curing times. Avoid applying stress to the bond during the curing process.

Environmental Conditions

Consider the environmental conditions when selecting and applying black double sided mounting tape. Temperature, humidity, and UV exposure can affect the performance of the adhesive. Choose a tape that is designed to withstand the specific environmental conditions of the application.

Choosing the Right Tape

Selecting the right black double sided mounting tape for the application is essential for achieving optimal results. Consider the following factors when choosing a tape:

- Adhesive Type: Choose an adhesive type that is compatible with the materials being bonded. Acrylic adhesives are generally suitable for a wide range of materials, while rubber adhesives provide excellent initial tack on irregular surfaces.

- Carrier Type: Select a carrier type that provides the desired properties, such as cushioning, gap filling, or dimensional stability. Foam carriers are ideal for uneven surfaces, while film carriers offer high strength.

- Thickness: Choose a tape thickness that is appropriate for the application. Thicker tapes can fill larger gaps, while thinner tapes provide a more discreet appearance.

- Temperature Resistance: Select a tape that can withstand the expected temperature range of the application.

- UV Resistance: For outdoor applications, choose a tape that is resistant to UV exposure.

Troubleshooting Common Issues

Even with careful application, issues can sometimes arise when using black double sided mounting tape. Here are some common problems and their solutions:

Poor Adhesion

If the tape is not adhering properly, it may be due to inadequate surface preparation. Ensure that the surfaces are clean, dry, and free from contaminants. Consider using a primer to improve adhesion on porous surfaces. Also, check that the adhesive is compatible with the materials being bonded.

Tape Failure

Tape failure can occur if the tape is not strong enough for the application. Choose a tape with a higher strength rating or consider using a stronger adhesive. Ensure that the tape is applied evenly and firmly to both surfaces. Avoid exceeding the weight limit of the tape.

Residue

Some black double sided mounting tape may leave residue behind when removed. Choose a tape that is designed to be residue-free or use a suitable adhesive remover to clean the surfaces after removal. Test the adhesive remover on a small, inconspicuous area first to ensure that it does not damage the surface.

Conclusion

Black double sided mounting tape is a versatile and reliable adhesive solution for a wide range of applications. Its strong bond, clean appearance, and ease of use make it a popular choice for professionals and DIY enthusiasts alike. By understanding its composition, advantages, applications, and best practices, you can maximize its effectiveness and achieve optimal results. Whether you’re mounting signs, assembling components, or tackling a home improvement project, black double sided mounting tape is a valuable tool to have in your arsenal. When selecting your tape, consider the specific requirements of your project to choose the right type of black double sided mounting tape for the job. Remember that proper surface preparation and application techniques are critical for achieving a strong and lasting bond. With the right approach, black double sided mounting tape can provide a reliable and aesthetically pleasing solution for all your mounting needs.