Sodium Acrylate: Unveiling the Science, Uses, and Safety of this Versatile Polymer

Sodium acrylate is a synthetic polymer with a wide range of applications, from diapers to detergents. Its remarkable ability to absorb and retain water makes it a crucial ingredient in numerous consumer and industrial products. This article delves into the science behind sodium acrylate, exploring its synthesis, properties, diverse uses, and safety considerations. We’ll examine how this compound, derived from acrylic acid, has revolutionized various industries and continues to be a subject of ongoing research and development.

What is Sodium Acrylate?

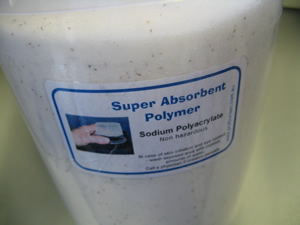

Sodium acrylate is the sodium salt of acrylic acid. It’s a white, odorless, granular solid that’s highly soluble in water. Its chemical formula is CH2=CHCOONa. The key characteristic of sodium acrylate lies in its ability to polymerize, forming long chains of repeating units. This polymerization process results in poly(sodium acrylate), also known as superabsorbent polymer (SAP).

The term ‘acrylate’ refers to salts, esters, and conjugates of acrylic acid. Acrylic acid itself is produced industrially from propylene, a byproduct of petroleum refining. The process involves oxidizing propylene to acrolein, followed by further oxidation to acrylic acid. This acrylic acid is then neutralized with sodium hydroxide (NaOH) to produce sodium acrylate.

Synthesis of Sodium Acrylate

The synthesis of sodium acrylate typically involves the neutralization of acrylic acid with a sodium base, such as sodium hydroxide. The reaction is exothermic, meaning it releases heat. Careful control of the reaction conditions, including temperature and pH, is crucial to ensure a high-quality product. The resulting sodium acrylate solution can then be dried to obtain the solid form.

The polymerization of sodium acrylate to form poly(sodium acrylate) is typically initiated by free radicals. These free radicals can be generated by various methods, including the use of chemical initiators or exposure to ultraviolet (UV) radiation. The polymerization process can be carried out in solution or in suspension, depending on the desired properties of the final polymer. [See also: Polyacrylate Uses and Applications]

Properties of Sodium Acrylate and Poly(Sodium Acrylate)

Sodium acrylate, in its monomer form, is water-soluble. However, it is the polymer, poly(sodium acrylate), that exhibits the most remarkable properties. Poly(sodium acrylate) is a superabsorbent polymer (SAP), capable of absorbing hundreds of times its weight in water. This exceptional water absorption capacity is due to the presence of numerous hydrophilic (water-loving) carboxylate groups (-COO–) along the polymer chain. These groups attract and bind water molecules, causing the polymer to swell dramatically.

Here are some key properties of poly(sodium acrylate):

- High water absorbency: Can absorb 200-300 times its weight in deionized water, and around 30-60 times its weight in saline solution.

- Water retention: Retains absorbed water even under pressure.

- Biodegradability: While not readily biodegradable, research is ongoing to develop biodegradable versions.

- Non-toxic: Generally considered non-toxic in its polymerized form.

Applications of Sodium Acrylate and Poly(Sodium Acrylate)

The unique properties of sodium acrylate and its polymer, poly(sodium acrylate), have led to its widespread use in various applications. Here are some notable examples:

Personal Care Products

The most well-known application of poly(sodium acrylate) is in disposable diapers. Its superabsorbent properties allow diapers to efficiently absorb and retain urine, keeping babies dry and comfortable. It is also used in feminine hygiene products for similar reasons. The polymer’s ability to lock in moisture also makes it suitable for use in wound dressings and other medical applications. [See also: Superabsorbent Polymers in Healthcare]

Agriculture

In agriculture, poly(sodium acrylate) is used as a soil amendment to improve water retention. When added to soil, it absorbs water during rainfall or irrigation and slowly releases it to the plants’ roots as needed. This can help to reduce water consumption, improve crop yields, and enhance drought resistance. It is particularly beneficial in sandy soils with poor water-holding capacity.

Industrial Applications

Sodium acrylate is used in a variety of industrial applications, including:

- Detergents: As a thickening agent and stabilizer.

- Adhesives: To improve bond strength and water resistance.

- Coatings: To enhance water resistance and durability.

- Water treatment: As a flocculant to remove suspended solids from water.

- Oil drilling: To control viscosity and fluid loss in drilling muds.

Food Packaging

Certain grades of poly(sodium acrylate) are approved for use in food packaging. Its ability to absorb moisture can help to prevent spoilage and extend the shelf life of food products. It is often used in absorbent pads placed in meat and poultry packaging to absorb excess fluids.

Safety Considerations

While poly(sodium acrylate) is generally considered safe in its polymerized form, there are some safety considerations to be aware of. The monomer, sodium acrylate, can be irritating to the skin, eyes, and respiratory tract. Therefore, it is important to handle it with care and avoid contact with skin and eyes. Appropriate personal protective equipment, such as gloves and safety glasses, should be worn when handling sodium acrylate.

Inhalation of sodium acrylate dust can also cause respiratory irritation. It is important to work in a well-ventilated area and to use a dust mask if necessary. In case of skin or eye contact, flush the affected area with plenty of water for at least 15 minutes. If irritation persists, seek medical attention.

It’s also worth noting that while poly(sodium acrylate) is non-toxic, ingestion of large quantities can cause gastrointestinal distress. Therefore, it is important to keep products containing poly(sodium acrylate), such as diapers, out of the reach of children.

The Future of Sodium Acrylate

Research and development efforts are ongoing to improve the properties and applications of sodium acrylate and poly(sodium acrylate). One area of focus is the development of biodegradable versions of the polymer. This would help to reduce the environmental impact of products containing poly(sodium acrylate), such as disposable diapers. [See also: Biodegradable Polymers: A Sustainable Solution]

Another area of research is the development of new applications for sodium acrylate. For example, researchers are exploring its use in drug delivery systems, tissue engineering, and other biomedical applications. The unique properties of sodium acrylate make it a promising material for these advanced applications.

Conclusion

Sodium acrylate is a versatile polymer with a wide range of applications. Its remarkable ability to absorb and retain water has made it an indispensable ingredient in numerous consumer and industrial products. From diapers to detergents, sodium acrylate plays a crucial role in improving our daily lives. While safety considerations are important, the benefits of sodium acrylate far outweigh the risks. As research and development efforts continue, we can expect to see even more innovative applications of this remarkable polymer in the future. The future of sodium acrylate looks bright, with ongoing research paving the way for more sustainable and advanced applications. Its continued importance in various industries ensures its place as a key chemical compound for years to come. Understanding its properties and safe handling is vital for maximizing its benefits while minimizing potential risks.