Precision Perfected: Exploring CNC Acrylic Services for Your Project Needs

In today’s fast-paced manufacturing and design landscape, precision is paramount. When it comes to materials like acrylic, achieving that level of accuracy often requires specialized services. CNC acrylic services, leveraging Computer Numerical Control technology, offer a sophisticated solution for cutting, shaping, and engraving acrylic sheets with unparalleled precision. This article delves into the world of CNC acrylic services, exploring their applications, benefits, and what to consider when choosing a provider. Whether you’re an engineer, designer, or hobbyist, understanding the capabilities of CNC acrylic services can unlock new possibilities for your projects.

What are CNC Acrylic Services?

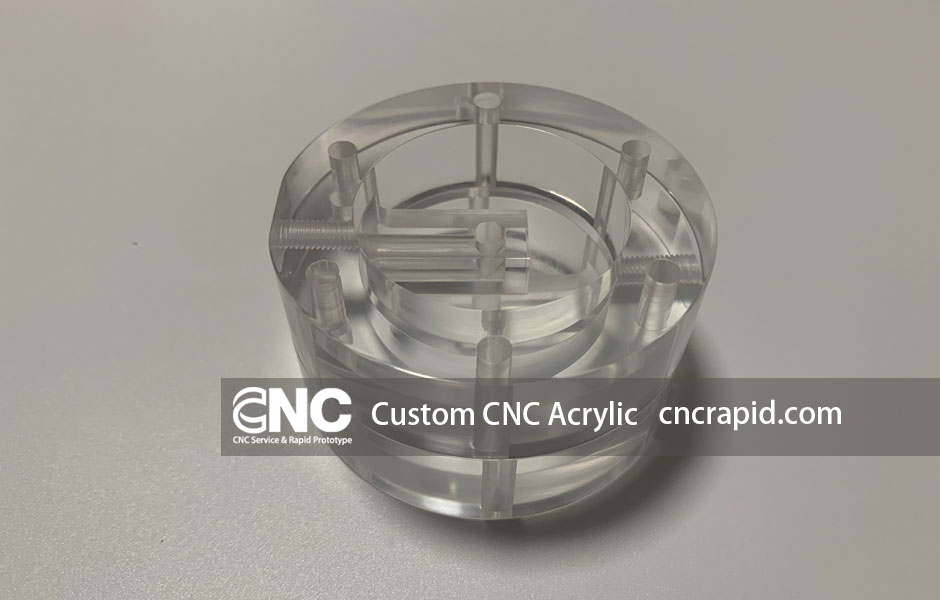

CNC acrylic services utilize computer-controlled machines to precisely cut, engrave, or shape acrylic sheets. Unlike manual methods, CNC machining relies on pre-programmed instructions to guide cutting tools, ensuring consistent and accurate results. This process allows for intricate designs, tight tolerances, and repeatable production, making it ideal for a wide range of applications.

The process typically begins with a digital design, often created using CAD (Computer-Aided Design) software. This design is then converted into a CNC program, which dictates the movements of the cutting tool. The acrylic sheet is secured to the CNC machine, and the program is executed, resulting in a precisely machined part. The versatility of CNC acrylic services stems from their ability to handle various thicknesses and grades of acrylic, as well as complex geometries.

Benefits of Using CNC Acrylic Services

Choosing CNC acrylic services offers several advantages over traditional fabrication methods:

- Precision and Accuracy: CNC machining ensures consistent and accurate cuts, even for complex designs. Tolerances can be held to within a few thousandths of an inch, resulting in parts that fit together perfectly.

- Repeatability: Once a CNC program is created, it can be used to produce identical parts repeatedly. This is crucial for mass production or when replacing damaged components.

- Complex Geometries: CNC machines can create intricate shapes and designs that would be difficult or impossible to achieve manually. This opens up new possibilities for product design and innovation.

- Material Efficiency: CNC machining optimizes material usage, minimizing waste and reducing costs. The nesting capabilities of CNC software allow for efficient placement of parts on the acrylic sheet.

- Fast Turnaround Times: CNC machines can operate continuously, allowing for faster production times compared to manual methods. This is especially important for projects with tight deadlines.

- Smooth Edges and Finishes: CNC acrylic services can produce parts with smooth edges and excellent surface finishes, reducing the need for post-processing.

Applications of CNC Acrylic Services

The versatility of CNC acrylic services makes them suitable for a wide array of applications across various industries:

Signage and Displays

Acrylic is a popular material for signage and displays due to its clarity, durability, and aesthetic appeal. CNC acrylic services can be used to create custom signs, logos, point-of-sale displays, and illuminated signs with precise cuts and intricate designs. The ability to engrave acrylic also allows for the creation of detailed graphics and text.

Architectural Models

Architects and designers often use acrylic to create detailed models of buildings and structures. CNC acrylic services provide the precision needed to accurately represent architectural features, such as windows, doors, and walls. The transparency of acrylic also allows for the creation of realistic lighting effects.

Medical Devices

Acrylic is a biocompatible material that is commonly used in medical devices and equipment. CNC acrylic services can be used to manufacture components such as housings, trays, and instrument panels with tight tolerances and smooth finishes. The ability to sterilize acrylic makes it suitable for use in medical environments.

Industrial Components

Acrylic is used in a variety of industrial applications due to its strength, durability, and resistance to chemicals. CNC acrylic services can be used to create custom components such as machine guards, enclosures, and panels. The ability to machine acrylic to precise dimensions ensures proper fit and function.

Consumer Products

Acrylic is a popular material for consumer products such as display cases, furniture, and decorative items. CNC acrylic services can be used to create custom designs and intricate shapes that enhance the aesthetic appeal of these products. The ability to polish acrylic to a high gloss finish adds to its visual appeal.

Electronics Enclosures

Acrylic offers a lightweight and durable solution for electronic enclosures. CNC acrylic services allow for precise cutouts for connectors, switches, and displays, ensuring a perfect fit for electronic components. The transparency of acrylic also allows for easy viewing of internal components.

Choosing a CNC Acrylic Service Provider

Selecting the right CNC acrylic service provider is crucial for ensuring the success of your project. Consider the following factors when making your decision:

- Experience and Expertise: Look for a provider with extensive experience in machining acrylic. They should have a deep understanding of the material’s properties and the best machining techniques to achieve the desired results.

- Equipment and Technology: Ensure that the provider has state-of-the-art CNC machines and software. This will enable them to handle complex designs and maintain tight tolerances.

- Material Selection: The provider should offer a wide range of acrylic materials, including different thicknesses, colors, and grades. This will allow you to choose the best material for your specific application.

- Quality Control: The provider should have a robust quality control process in place to ensure that all parts meet your specifications. This includes dimensional inspection, surface finish analysis, and material testing.

- Turnaround Time: Discuss your project timeline with the provider and ensure that they can meet your deadlines. Ask about their production capacity and lead times.

- Pricing: Obtain quotes from multiple providers and compare their pricing. Be sure to factor in the cost of materials, machining time, and any additional services such as design assistance or finishing.

- Customer Service: Choose a provider that offers excellent customer service and is responsive to your needs. They should be willing to answer your questions, provide technical support, and work with you to ensure your satisfaction.

Design Considerations for CNC Acrylic Machining

To ensure the best results from CNC acrylic services, consider the following design guidelines:

- Minimum Feature Size: Avoid designing features that are too small or delicate, as they may be difficult to machine accurately. A general rule of thumb is to maintain a minimum feature size of 1mm.

- Corner Radii: Sharp corners can be stress concentrators and may be prone to cracking. Incorporate radii in internal corners to improve the strength and durability of the part.

- Hole Diameters: When designing holes, consider the size of the cutting tools that will be used. Smaller holes may require special tooling and may be more expensive to machine.

- Material Thickness: Choose an appropriate material thickness for your application. Thicker materials are stronger and more rigid, but they may also be more expensive to machine.

- Tolerances: Specify tolerances that are achievable with CNC acrylic services. Tighter tolerances will increase the cost of machining.

- Draft Angles: If you are designing parts that will be molded, incorporate draft angles to facilitate part removal from the mold.

The Future of CNC Acrylic Services

The future of CNC acrylic services is bright, with ongoing advancements in technology and materials. Expect to see further improvements in precision, speed, and automation, as well as the development of new acrylic materials with enhanced properties. As demand for custom and intricate designs continues to grow, CNC acrylic services will play an increasingly important role in manufacturing and design.

The integration of AI and machine learning into CNC machining processes will further optimize cutting parameters, reduce waste, and improve overall efficiency. Additionally, the rise of additive manufacturing (3D printing) may lead to hybrid manufacturing processes that combine the strengths of both CNC machining and 3D printing. [See also: 3D Printing with Acrylic]

Conclusion

CNC acrylic services offer a powerful and versatile solution for creating precise and complex parts from acrylic. By understanding the benefits, applications, and design considerations of CNC acrylic services, you can leverage this technology to bring your ideas to life. Whether you’re creating signage, architectural models, medical devices, or consumer products, CNC acrylic services can help you achieve the highest levels of quality and precision. Remember to carefully evaluate potential providers to ensure they have the experience, equipment, and expertise to meet your specific needs. With the right partner, you can unlock the full potential of acrylic and create truly exceptional products. The precision and accuracy offered by CNC acrylic services are unmatched, making them an invaluable asset for any project requiring intricate designs and tight tolerances. Choosing the right CNC acrylic service is an investment in the quality and success of your project, ensuring a finished product that meets your exact specifications. From prototyping to mass production, CNC acrylic services provide a cost-effective and efficient solution for all your acrylic machining needs. The possibilities are endless with CNC acrylic services, allowing you to create innovative and visually stunning products that stand out from the competition. So, explore the world of CNC acrylic services and discover how they can transform your ideas into reality. Don’t hesitate to reach out to experienced providers to discuss your project and get started on your next masterpiece. The expertise of professionals in CNC acrylic services can guide you through the design and manufacturing process, ensuring a seamless and successful outcome. With the right approach, CNC acrylic services can be the key to unlocking your creative potential and achieving remarkable results.