How to Drill Out a Stripped Screw: A Comprehensive Guide

Dealing with a stripped screw can be one of the most frustrating experiences for DIY enthusiasts and professionals alike. A screw becomes stripped when the head is damaged, preventing a screwdriver from gripping properly. This often happens due to excessive force, using the wrong size screwdriver, or working with low-quality screws. Instead of giving up on your project, knowing how to drill out a stripped screw is an invaluable skill. This guide provides a comprehensive, step-by-step approach to safely and effectively removing stripped screws.

Understanding Stripped Screws

Before diving into the techniques, it’s important to understand why screws get stripped in the first place. Common causes include:

- Over-tightening: Applying too much force when tightening a screw can damage the head.

- Incorrect Screwdriver Size: Using a screwdriver that is too small or the wrong type (e.g., using a Phillips head screwdriver on a Pozidriv screw) can lead to stripping.

- Soft Metal Screws: Low-quality screws made from soft metals are more susceptible to damage.

- Angle Issues: Driving the screw at an angle can cause the screwdriver to slip and strip the head.

Recognizing these causes can help prevent future stripping.

Tools and Materials Needed

To successfully drill out a stripped screw, you’ll need the following tools and materials:

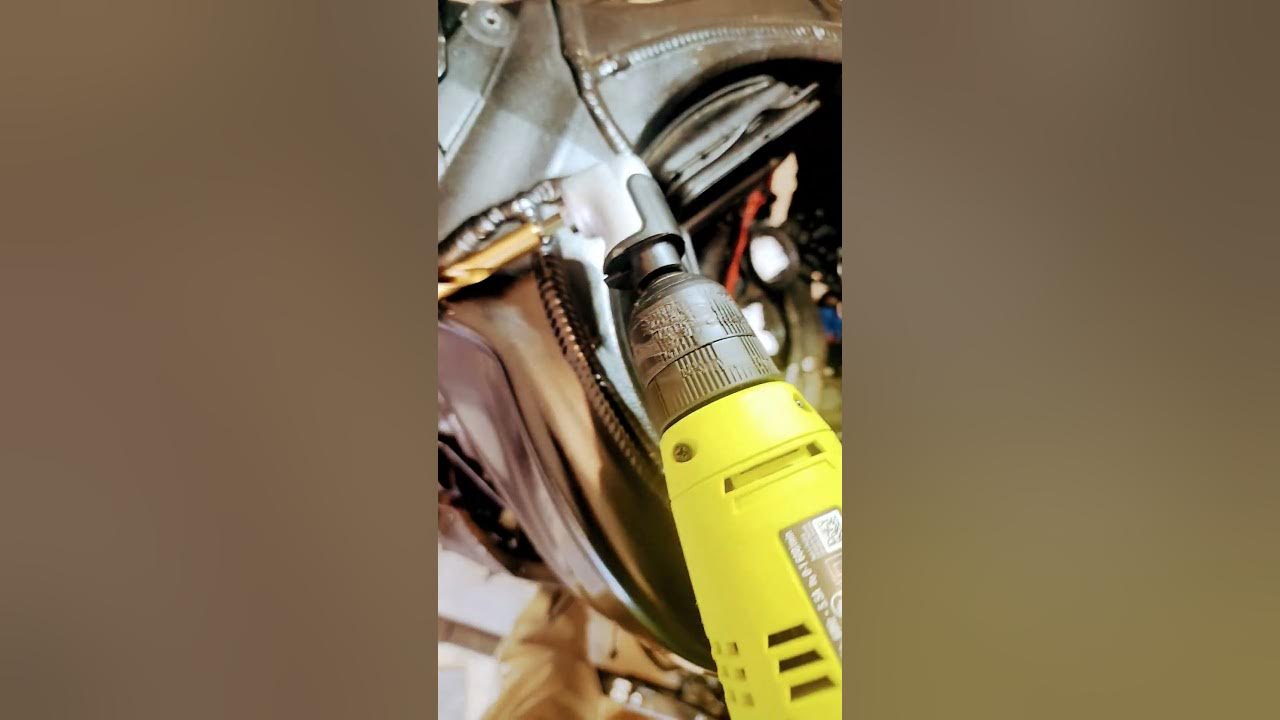

- Drill: A power drill is essential for this task. Cordless drills offer greater mobility.

- Screw Extractor Set: These sets typically include various sizes of extractors designed to grip and remove damaged screws.

- Drill Bits: A set of high-speed steel (HSS) drill bits is necessary. Choose a bit slightly smaller than the screw’s shank.

- Center Punch and Hammer: These are used to create a pilot point for the drill bit, preventing it from wandering.

- Safety Glasses: Protecting your eyes from flying debris is crucial.

- Gloves: Provide a better grip and protect your hands.

- Penetrating Oil (Optional): Can help loosen stubborn screws.

- Masking Tape (Optional): Protects the surrounding surface from scratches.

Step-by-Step Guide to Drilling Out a Stripped Screw

Step 1: Preparation

Start by preparing the work area. Clean the area around the stripped screw and apply masking tape to protect the surrounding surface from accidental scratches. This is particularly important when working on delicate materials like wood or painted surfaces. Put on your safety glasses and gloves.

Step 2: Create a Pilot Point

Using the center punch and hammer, gently create a pilot point in the center of the stripped screw head. This indentation will guide the drill bit and prevent it from slipping. A well-placed pilot point is critical for accurate drilling. If you’re having trouble finding the center, use a magnifying glass for better visibility.

Step 3: Drill a Pilot Hole

Select a drill bit that is smaller than the screw’s shank (the smooth part of the screw). Place the drill bit on the pilot point and begin drilling slowly and steadily. Apply gentle pressure, allowing the drill to do the work. Avoid applying excessive force, which can break the drill bit or further damage the screw. Drill straight down into the screw head, creating a pilot hole deep enough for the screw extractor to grip. If the screw is particularly stubborn, consider applying a small amount of penetrating oil before drilling. [See also: Removing Rusted Screws]

Step 4: Insert the Screw Extractor

Choose a screw extractor that matches the size of the pilot hole you just drilled. Insert the extractor into the hole. Most screw extractors are designed to be used in reverse. This means you’ll need to set your drill to the reverse setting (counterclockwise). Apply firm, steady pressure while turning the drill slowly. The extractor should bite into the screw head and begin to turn it out. If the extractor slips, try using a slightly larger size or applying more pressure. The goal is to get a solid grip on the stripped screw head.

Step 5: Extract the Stripped Screw

Continue applying steady pressure and turning the drill in reverse. As the screw extractor grips the stripped screw, it should begin to turn out. Be patient and avoid using excessive force, which can break the extractor or damage the surrounding material. If the screw is particularly tight, try applying heat to the screw head with a heat gun or soldering iron. The heat can help loosen the screw’s threads. Once the screw is loose enough, you should be able to remove it completely. If you are trying to drill out a stripped screw in a tight area, using smaller tools can be extremely helpful.

Alternative Methods for Removing Stripped Screws

While drilling out a stripped screw is a common and effective method, there are alternative approaches you can try:

- Rubber Band Technique: Place a wide rubber band over the stripped screw head and insert the screwdriver. The rubber band can provide additional grip.

- Steel Wool: Similar to the rubber band technique, steel wool can fill the stripped screw head and provide a better grip for the screwdriver.

- Using a Larger Screwdriver: Sometimes, a slightly larger screwdriver can grip the damaged screw head.

- Impact Driver: An impact driver delivers a sudden rotational force, which can help loosen a stubborn screw.

- Screw Removal Pliers: These pliers are designed to grip the head of a screw and turn it out.

These methods may work in some cases, but drilling is often the most reliable solution.

Tips for Preventing Stripped Screws

Prevention is always better than cure. Here are some tips to help prevent screws from stripping in the first place:

- Use the Right Screwdriver: Always use the correct size and type of screwdriver for the screw.

- Apply Even Pressure: Apply firm, even pressure when driving screws.

- Avoid Overtightening: Do not overtighten screws. Stop when the screw is snug.

- Use High-Quality Screws: Invest in high-quality screws made from durable materials.

- Pre-Drill Pilot Holes: When working with hard materials, pre-drill pilot holes to prevent the screw from binding and stripping.

- Lubricate Screws: Applying a small amount of lubricant to the screw threads can help prevent them from seizing and stripping.

Choosing the Right Screw Extractor

Selecting the appropriate screw extractor is crucial for successfully removing a stripped screw. Screw extractor sets typically include multiple sizes to accommodate different screw sizes. When choosing an extractor, consider the following factors:

- Size: Select an extractor that matches the size of the pilot hole you drilled.

- Type: There are different types of screw extractors, including spiral fluted and straight fluted. Spiral fluted extractors are generally more effective for deeply stripped screws.

- Material: Look for extractors made from high-quality steel for durability.

Reading reviews and comparing different screw extractor sets can help you make an informed decision. [See also: Best Screw Extractor Sets]

Dealing with Different Types of Stripped Screws

The approach to drilling out a stripped screw may vary depending on the type of screw and the material it is embedded in. Here are some considerations for different scenarios:

Stripped Wood Screws

Wood screws are often easier to remove than metal screws because wood is a softer material. However, it’s important to avoid damaging the surrounding wood. Use a sharp drill bit and apply gentle pressure to prevent splintering. Consider using a screw extractor specifically designed for wood screws.

Stripped Metal Screws

Metal screws can be more challenging to remove due to their hardness. Use a high-speed steel (HSS) drill bit and apply penetrating oil to help loosen the screw. Be patient and avoid applying excessive force, which can break the drill bit or extractor. If the screw is particularly stubborn, consider using a screw removal pliers or an impact driver.

Stripped Screws in Plastic

Plastic is a delicate material that can easily crack or break. Use a slow drill speed and apply very light pressure. Consider using a screw extractor specifically designed for plastic screws. Avoid using heat, which can melt or warp the plastic.

Troubleshooting Common Issues

Even with the best tools and techniques, you may encounter challenges when trying to drill out a stripped screw. Here are some common issues and how to address them:

- The Drill Bit Keeps Slipping: Ensure you have a well-defined pilot point. Use a center punch and hammer to create a deeper indentation.

- The Screw Extractor Breaks: This usually happens when excessive force is applied. Use a smaller extractor and apply steady, even pressure.

- The Screw Won’t Budge: Apply penetrating oil and allow it to soak for several minutes. Try using heat to loosen the screw threads.

- The Surrounding Material is Damaged: Use masking tape to protect the surface. Apply gentle pressure and avoid using excessive force.

Safety Precautions

Safety should always be a top priority when working with power tools. Here are some important safety precautions to keep in mind when drilling out a stripped screw:

- Wear Safety Glasses: Protect your eyes from flying debris.

- Wear Gloves: Provide a better grip and protect your hands.

- Use a Dust Mask: Prevent inhalation of dust particles.

- Work in a Well-Ventilated Area: Ensure proper ventilation to avoid inhaling fumes.

- Disconnect Power: When working with electrical components, always disconnect the power source.

- Keep Your Work Area Clean: Prevent accidents by keeping your work area free of clutter.

Conclusion

Knowing how to drill out a stripped screw is a valuable skill that can save you time and frustration. By following the steps outlined in this guide, you can safely and effectively remove damaged screws and complete your projects with confidence. Remember to use the right tools, apply gentle pressure, and take your time. With practice, you’ll become proficient at removing stripped screws and preventing them from stripping in the future. If you encounter extremely stubborn cases, consider consulting a professional for assistance. Don’t let a stripped screw ruin your day; arm yourself with the knowledge and tools to tackle the problem head-on. Learning how to drill out a stripped screw is a worthwhile investment of your time and effort. This comprehensive guide should give you the confidence to tackle any stripped screw situation.