How to Cut Thick Acrylic Plastic: A Comprehensive Guide

Working with acrylic plastic, especially the thicker varieties, can seem daunting. However, with the right tools, techniques, and a healthy dose of patience, achieving clean and precise cuts is entirely possible. This guide provides a comprehensive overview of how to cut thick acrylic plastic, covering everything from preparation to finishing touches, ensuring your projects look professional and polished. We’ll explore various methods, safety precautions, and tips to minimize chipping and cracking, common challenges when working with this versatile material.

Understanding Acrylic Plastic

Before diving into the cutting process, it’s essential to understand the properties of acrylic plastic. Also known as Plexiglas or Lucite, acrylic is a transparent thermoplastic often used as a lightweight and shatter-resistant alternative to glass. It’s available in various thicknesses, from thin sheets to substantial blocks. The thickness significantly impacts the cutting approach.

Thick acrylic, generally considered anything over ¼ inch (6mm), requires more deliberate techniques than thinner sheets. Due to its density, using the wrong method can lead to cracking, melting, or uneven edges. Knowing the type of acrylic you’re working with (cast or extruded) also influences the best cutting strategy. Cast acrylic is generally preferred for machining and cutting because it’s less prone to melting and chipping compared to extruded acrylic.

Essential Tools for Cutting Thick Acrylic

Selecting the right tools is paramount for successfully cutting thick acrylic plastic. Here’s a breakdown of the most effective options:

- Table Saw: Ideal for straight cuts on large sheets. A blade specifically designed for plastics is crucial.

- Circular Saw: A portable option for straight cuts, especially useful for on-site work. Again, use a plastic-cutting blade.

- Jigsaw: Suitable for curved or intricate cuts. A fine-tooth blade and variable speed control are essential.

- Laser Cutter: Provides incredibly precise and clean cuts, but requires specialized equipment. This is often the best method for complex shapes and intricate designs in thick acrylic plastic.

- Router: Useful for creating grooves, edges, and shaping acrylic.

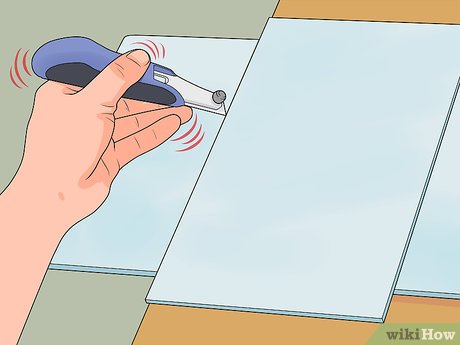

- Scoring Knife/Acrylic Cutter: For thinner acrylic sheets, scoring and snapping can be an effective method. However, this is generally not recommended for cutting thick acrylic plastic.

Beyond the cutting tool, you’ll also need:

- Safety Glasses: Protect your eyes from flying debris.

- Dust Mask: Acrylic dust can be an irritant.

- Clamps: Secure the acrylic sheet to your work surface.

- Straight Edge/Guide: Ensure accurate straight cuts.

- Lubricant (optional): Can help reduce friction and heat, especially when using a saw.

Preparing to Cut Thick Acrylic Plastic

Proper preparation is key to achieving a clean and successful cut. Follow these steps:

- Clean the Acrylic: Remove any dirt, dust, or debris from the surface. Use a mild soap and water solution and a soft cloth.

- Mark the Cutting Line: Use a fine-tip marker or grease pencil to clearly mark the desired cutting line. Accuracy is crucial.

- Secure the Acrylic: Clamp the acrylic sheet firmly to your work surface. Ensure the clamps are positioned so they won’t interfere with the cutting path.

- Choose the Right Blade: Select a blade specifically designed for cutting plastics. These blades typically have a high tooth count and a low rake angle to minimize chipping. For a table saw, a triple-chip grind blade is often recommended.

- Adjust the Saw Speed: If your saw has variable speed control, set it to a lower speed. This helps prevent the acrylic from melting due to friction.

Step-by-Step Cutting Guide

Here’s a detailed guide on how to cut thick acrylic plastic using a table saw, a common and effective method:

- Set Up the Table Saw: Install the plastic-cutting blade and adjust the blade height so it’s slightly higher than the thickness of the acrylic sheet.

- Adjust the Fence: Position the fence to the desired width for your cut. Double-check the measurement to ensure accuracy.

- Make a Test Cut: Before cutting the actual piece, make a test cut on a scrap piece of acrylic. This allows you to fine-tune the saw speed and blade height and observe the cut quality.

- Feed the Acrylic Slowly: Push the acrylic sheet through the saw blade at a slow and consistent pace. Avoid forcing the material, as this can cause chipping or cracking.

- Use a Push Stick: As you approach the end of the cut, use a push stick to safely guide the acrylic past the blade. This helps prevent kickback and keeps your hands away from the blade.

- Cool the Blade (Optional): If you’re making multiple cuts, consider periodically cooling the blade with compressed air or a coolant to prevent overheating.

Alternative Cutting Methods

Using a Circular Saw

The process for using a circular saw to cut thick acrylic plastic is similar to using a table saw. The key differences are that the saw is portable and you’ll need to use a straight edge as a guide. Clamp the straight edge securely to the acrylic sheet and follow the same steps as above, ensuring a slow and steady feed rate.

Using a Jigsaw

A jigsaw is ideal for curved or intricate cuts. Use a fine-tooth blade designed for plastics and set the saw to a low speed. Apply gentle pressure and follow the marked cutting line carefully. Consider using a lubricant to reduce friction and prevent the acrylic from melting. Because of the nature of a jigsaw, cutting very thick acrylic plastic with this tool can be more challenging and may result in less clean edges.

Laser Cutting

Laser cutting offers the most precise and clean cuts for thick acrylic plastic. This method uses a focused laser beam to vaporize the material, resulting in smooth edges and intricate designs. However, laser cutters are expensive and require specialized knowledge to operate. If you need highly precise cuts or complex shapes, consider outsourcing the job to a laser cutting service. This is often the preferred method for industrial applications and artistic designs involving thick acrylic plastic.

Troubleshooting Common Issues

Even with careful preparation, you may encounter some common issues when cutting thick acrylic plastic:

- Chipping: This is often caused by using the wrong blade or feeding the material too quickly. Ensure you’re using a plastic-cutting blade and reduce the feed rate.

- Melting: Friction can cause the acrylic to melt, especially when cutting at high speeds. Reduce the saw speed and consider using a lubricant.

- Cracking: This can occur if the acrylic is stressed or if the blade is too aggressive. Avoid forcing the material and use a blade with a high tooth count.

- Uneven Edges: Inconsistent feed rate or blade wobble can lead to uneven edges. Maintain a steady feed rate and ensure the blade is properly aligned.

Finishing Touches

After cutting the acrylic, you may need to refine the edges. Here are some common finishing techniques:

- Sanding: Use fine-grit sandpaper (220 grit or higher) to smooth any rough edges or imperfections. Wet sanding can help reduce friction and prevent the acrylic from melting.

- Polishing: Use a plastic polish and a soft cloth to restore the clarity of the acrylic and remove any scratches.

- Flame Polishing: A specialized technique that uses a flame to melt the surface of the acrylic, creating a smooth and glossy edge. This requires practice and caution.

Safety Precautions

Safety should always be a top priority when working with power tools. Always wear safety glasses and a dust mask to protect yourself from flying debris and acrylic dust. Use clamps to secure the acrylic sheet and keep your hands away from the blade. If you’re using a table saw or circular saw, use a push stick to guide the material past the blade. Work in a well-ventilated area to avoid inhaling acrylic fumes.

Conclusion

Cutting thick acrylic plastic requires careful planning, the right tools, and a steady hand. By following the steps outlined in this guide, you can achieve clean and precise cuts for your projects. Remember to prioritize safety and take your time. With practice, you’ll be able to confidently work with this versatile material and create stunning designs. Whether you are creating displays, signage, or custom parts, understanding how to cut thick acrylic plastic opens up a world of possibilities. Don’t be afraid to experiment with different techniques to find what works best for you, and always prioritize safety when working with power tools. [See also: Acrylic Fabrication Techniques] [See also: Working with Plexiglass] [See also: Best Blades for Cutting Plastic]