Decoding Efficiency: The Power of Tool Labels in Modern Workspaces

In today’s fast-paced, highly organized professional environments, efficiency is paramount. Every second counts, and minimizing wasted time searching for the right tool can significantly impact productivity. One of the simplest yet most effective strategies for achieving this is through the consistent and strategic use of tool labels. These seemingly small identifiers play a crucial role in streamlining workflows, reducing errors, and fostering a more organized and productive workspace. This article delves into the importance of tool labels, exploring their benefits, best practices for implementation, and the wide range of applications across various industries.

The Undeniable Benefits of Tool Labels

The advantages of implementing a comprehensive tool label system are multifaceted. They extend beyond mere identification, impacting various aspects of workplace efficiency and safety.

Enhanced Organization and Accessibility

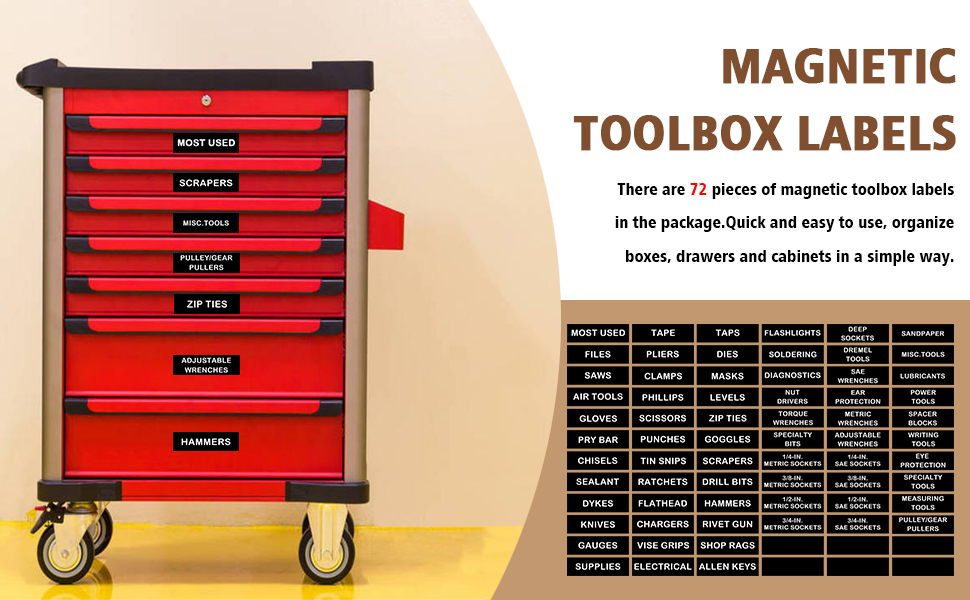

Perhaps the most obvious benefit is improved organization. When tools are clearly labeled, it becomes significantly easier to locate the specific item needed. This reduces the time spent searching, allowing employees to focus on their core tasks. A well-labeled toolbox, for example, eliminates the frustration of rummaging through a disorganized mess, ensuring that the right wrench, screwdriver, or measuring tape is readily available. This is especially critical in time-sensitive situations where every second counts.

Reduced Errors and Improved Accuracy

Clear tool labels minimize the risk of using the wrong tool for a particular job. This is particularly important in industries where precision is essential, such as manufacturing, engineering, and healthcare. Using the wrong tool can lead to errors, damage to equipment, and even safety hazards. By clearly identifying each tool and its intended purpose, tool labels contribute to a safer and more accurate work environment.

Increased Efficiency and Productivity

The combined effect of improved organization and reduced errors directly translates to increased efficiency and productivity. When employees can quickly locate the tools they need and are confident that they are using the correct ones, they can complete tasks more quickly and effectively. This leads to higher output, reduced downtime, and ultimately, improved profitability. The implementation of tool labels is a simple yet powerful way to optimize workflows and maximize productivity.

Improved Safety and Compliance

In many industries, safety is a top priority. Tool labels can play a vital role in promoting a safer work environment by clearly identifying hazardous tools and equipment. For example, power tools should be clearly labeled with warnings and safety instructions. Similarly, tools used for handling hazardous materials should be clearly identified to prevent accidental exposure. Furthermore, in regulated industries, proper tool labeling may be a compliance requirement. Adhering to these standards helps ensure a safe and legally compliant workplace.

Cost Savings

While the initial investment in tool labels and a labeling system may seem like an added expense, the long-term cost savings can be significant. By reducing errors, minimizing downtime, and improving efficiency, tool labels contribute to a more streamlined and profitable operation. Furthermore, properly labeled and organized tools are less likely to be lost or damaged, reducing the need for replacements. This translates to significant cost savings over time.

Best Practices for Implementing a Tool Label System

To maximize the benefits of tool labels, it’s essential to implement a well-planned and consistently applied system. Here are some best practices to consider:

Choose Durable and Appropriate Labels

The type of tool label you choose will depend on the specific application and the environment in which the tools will be used. Consider factors such as temperature, humidity, exposure to chemicals, and the frequency of use. Durable materials like vinyl, polyester, or metal are often the best choice for long-lasting tool labels. Ensure the adhesive is strong enough to withstand the rigors of daily use. For environments with harsh conditions, consider using laminated or weatherproof tool labels.

Use Clear and Concise Language

The language used on tool labels should be clear, concise, and easy to understand. Avoid jargon or technical terms that may not be familiar to all employees. Use standardized terminology and abbreviations whenever possible. The font size should be large enough to be easily read from a reasonable distance. Consider using color-coding to further enhance clarity and visual identification. For example, different colors could be used to represent different types of tools or different departments.

Standardize Labeling Practices

Consistency is key to an effective tool label system. Develop a standardized labeling procedure and ensure that all employees are trained on how to properly label tools. This includes specifying the placement of tool labels, the information to be included, and the font style and size to be used. Regular audits should be conducted to ensure that tool labeling standards are being maintained. A standardized approach ensures that the system is easy to use and understand for everyone.

Regularly Maintain and Update Labels

Tool labels are not a one-time investment. They require regular maintenance and updates to ensure that they remain legible and accurate. Damaged or faded tool labels should be replaced promptly. As new tools are acquired, they should be immediately labeled according to the established standards. Regularly review the tool labeling system to identify areas for improvement and to ensure that it continues to meet the evolving needs of the organization. Obsolete or inaccurate tool labels can lead to confusion and errors, negating the benefits of the system.

Involve Employees in the Process

The success of any tool label system depends on the buy-in and participation of employees. Involve employees in the development and implementation of the system. Solicit their feedback on the types of information that should be included on the tool labels and the best ways to organize and manage the tools. This fosters a sense of ownership and encourages employees to take responsibility for maintaining the system. When employees feel invested in the process, they are more likely to adhere to the standards and contribute to the overall success of the program.

Applications Across Industries

The benefits of tool labels are applicable across a wide range of industries, from manufacturing and construction to healthcare and education. Here are a few examples:

Manufacturing

In manufacturing environments, tool labels are essential for maintaining efficiency and safety. They help workers quickly locate the right tools for specific tasks, reducing downtime and minimizing errors. Tool labels can also be used to identify tools that require maintenance or calibration. [See also: Predictive Maintenance Strategies in Manufacturing] By clearly labeling tools with their calibration dates, manufacturers can ensure that equipment is functioning properly and that products meet quality standards.

Construction

Construction sites are often chaotic and demanding environments. Tool labels can help keep tools organized and prevent loss or theft. By labeling tools with the company name and contact information, contractors can increase the chances of recovering lost or stolen equipment. Tool labels can also be used to identify tools that require inspection or repair. This helps ensure that tools are safe to use and that construction projects are completed on time and within budget.

Healthcare

In healthcare settings, tool labels are critical for preventing errors and ensuring patient safety. Medical instruments and equipment must be clearly labeled to avoid confusion and to ensure that the correct tools are used for each procedure. Tool labels can also be used to identify instruments that have been sterilized or disinfected. This helps prevent the spread of infection and ensures that patients receive the highest quality of care.

Education

In educational settings, tool labels can help students learn about different tools and their uses. By labeling tools in workshops and science labs, teachers can provide students with a hands-on learning experience. Tool labels can also be used to organize and manage tools, making it easier for students to find what they need. This helps create a more efficient and productive learning environment.

The Future of Tool Labeling

As technology continues to evolve, the future of tool labeling is likely to become even more sophisticated. We can anticipate the integration of smart tool labels that incorporate RFID technology or QR codes. These advanced tool labels could provide real-time tracking of tools, automated inventory management, and detailed information about tool usage and maintenance. Imagine a system where a simple scan of a tool label provides access to the tool’s maintenance history, safety instructions, and even video tutorials on its proper use. This level of integration would further enhance efficiency, safety, and compliance across various industries. [See also: The Impact of IoT on Workplace Safety]

Conclusion

Tool labels are a simple yet powerful tool for improving efficiency, reducing errors, and promoting safety in the workplace. By implementing a well-planned and consistently applied tool label system, organizations can reap significant benefits, including increased productivity, reduced costs, and improved compliance. Whether you’re in manufacturing, construction, healthcare, or education, tool labels can help you create a more organized, efficient, and safe work environment. Embrace the power of tool labels and unlock the full potential of your workforce.