Corrosion Removal: Methods, Prevention, and Best Practices

Corrosion, the gradual degradation of materials (usually metals) by chemical reaction with their environment, is a pervasive problem across industries. From infrastructure to manufacturing, the effects of corrosion can lead to structural failure, costly repairs, and even safety hazards. Effective corrosion removal is, therefore, crucial for maintaining the integrity and longevity of assets. This article delves into the various methods for corrosion removal, explores preventative measures, and outlines best practices to mitigate the impact of corrosion.

Understanding Corrosion

Before discussing corrosion removal, it’s important to understand what causes it. Corrosion is an electrochemical process that requires an electrolyte (like water), a metal, and an oxidizing agent (like oxygen). The most common form is rust, which affects iron and steel. Other metals, such as aluminum, copper, and zinc, also corrode, although the resulting compounds may offer some degree of protection to the underlying metal.

Types of Corrosion

- Uniform Corrosion: Affects the entire surface of a metal.

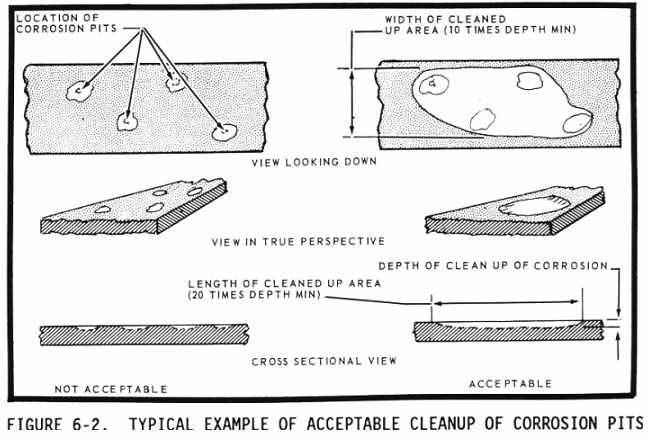

- Pitting Corrosion: Localized corrosion that creates small holes.

- Galvanic Corrosion: Occurs when two dissimilar metals are in contact in the presence of an electrolyte.

- Crevice Corrosion: Occurs in confined spaces where stagnant solutions can accumulate.

- Stress Corrosion Cracking: Cracking caused by the combined effects of tensile stress and a corrosive environment.

Methods for Corrosion Removal

Choosing the right method for corrosion removal depends on several factors, including the type of metal, the extent of the corrosion, and the desired finish. Here are some common techniques:

Mechanical Methods

Mechanical methods involve physically removing the corrosion products. These methods are often effective for removing heavy corrosion, but they can also damage the underlying metal if not used carefully.

- Abrasive Blasting: Uses pressurized air to propel abrasive materials (like sand, steel grit, or glass beads) against the corroded surface. This is a highly effective method for removing rust and scale, but it can be aggressive and may require specialized equipment.

- Wire Brushing: Involves using a wire brush to scrub away corrosion. This is a simpler method suitable for removing light to moderate corrosion.

- Grinding: Utilizes grinding wheels or discs to remove corroded material. Grinding can be effective for removing localized corrosion or surface imperfections.

- Sanding: Similar to wire brushing, sanding uses abrasive paper to remove corrosion. This is a less aggressive method suitable for finer finishes.

- Chipping and Scraping: Manual methods using tools like chisels and scrapers to remove loose corrosion. These methods are best for localized areas and heavy scale.

Chemical Methods

Chemical methods involve using chemical solutions to dissolve or loosen corrosion products. These methods can be effective for removing corrosion in hard-to-reach areas, but they require careful handling and disposal of chemicals.

- Acid Pickling: Involves immersing the corroded metal in an acid solution (like hydrochloric acid or sulfuric acid). The acid dissolves the rust and scale, leaving a clean metal surface. This method is commonly used in industrial settings but requires strict safety precautions.

- Chelating Agents: Use chelating agents (like EDTA) to bind to metal ions in the corrosion products, making them soluble and easy to remove. These agents are often less aggressive than acids and can be used on more delicate materials.

- Rust Converters: Convert rust into a stable, inert compound that can be painted over. These products contain chemicals that react with the rust to form a protective layer.

- Solvent Cleaning: Using solvents to dissolve oils, grease, and other contaminants that can contribute to corrosion. This is often a preliminary step before other corrosion removal methods.

Electrochemical Methods

Electrochemical methods use electrical current to remove corrosion. These methods are often used for cleaning and restoring metal objects.

- Electropolishing: Involves immersing the metal in an electrolyte and applying an electrical current to dissolve the surface layer, removing corrosion and creating a smooth, polished finish.

- Electrolytic Cleaning: Uses an electrolytic cell to remove corrosion products. The metal is made the cathode, and the electrolyte dissolves the corrosion, which is then deposited on the anode.

Laser Cleaning

Laser cleaning is a relatively new technology that uses focused laser beams to vaporize corrosion products without damaging the underlying metal. This method is precise, environmentally friendly, and can be used on a wide range of materials. However, it can be expensive.

Preventative Measures to Minimize Corrosion

While corrosion removal is essential, preventing corrosion in the first place is even more effective. Here are some key preventative measures:

Protective Coatings

- Paint: Provides a barrier between the metal and the environment, preventing moisture and oxygen from reaching the surface.

- Powder Coating: A dry finishing process where a powder is applied electrostatically and then cured with heat. Powder coatings offer excellent corrosion resistance and durability.

- Galvanizing: Coating steel or iron with a layer of zinc. The zinc acts as a sacrificial anode, corroding instead of the underlying metal.

- Anodizing: An electrochemical process that creates a thick, protective oxide layer on aluminum.

- Plating: Coating a metal with another metal (like chrome, nickel, or gold) to provide corrosion resistance and enhance appearance.

Material Selection

Choosing corrosion-resistant materials is crucial for preventing corrosion. Stainless steel, aluminum alloys, and copper alloys are all more resistant to corrosion than plain carbon steel. Selecting the right alloy for the specific environment can significantly reduce the risk of corrosion.

Environmental Control

- Dehumidification: Reducing the humidity in the environment can slow down the rate of corrosion.

- Inhibitors: Adding corrosion inhibitors to water or other fluids can reduce the rate of corrosion.

- Cathodic Protection: A technique that uses an external source of electricity to make the metal the cathode, preventing it from corroding. This is commonly used to protect pipelines and other underground structures.

Design Considerations

Proper design can also help prevent corrosion. Avoid creating crevices or pockets where moisture can accumulate. Ensure adequate drainage to prevent water from pooling on surfaces. Use compatible materials to avoid galvanic corrosion. [See also: Best Practices in Metal Fabrication]

Best Practices for Corrosion Removal

Regardless of the method used, following best practices is essential for effective and safe corrosion removal:

- Assess the Corrosion: Before starting any corrosion removal process, carefully assess the type and extent of the corrosion. This will help you choose the appropriate method and materials.

- Prepare the Surface: Clean the surface to remove any loose debris, dirt, or grease. This will ensure that the corrosion removal method is effective.

- Use the Right Equipment: Use the appropriate tools and equipment for the chosen corrosion removal method. Make sure the equipment is in good working condition and properly maintained.

- Follow Safety Precautions: Always follow safety precautions when working with chemicals or power tools. Wear appropriate personal protective equipment (PPE), such as gloves, eye protection, and respirators.

- Dispose of Waste Properly: Dispose of waste materials (like used chemicals, abrasive materials, and corrosion products) in accordance with local regulations.

- Inspect the Surface: After corrosion removal, thoroughly inspect the surface to ensure that all corrosion has been removed. Repair any damage to the underlying metal.

- Apply Protective Coatings: After corrosion removal, apply a protective coating to prevent future corrosion. Choose a coating that is compatible with the metal and the environment.

- Document the Process: Keep a record of the corrosion removal process, including the methods used, the materials used, and the results. This information can be helpful for future maintenance and repairs.

Conclusion

Corrosion removal is a critical aspect of maintenance and asset management. By understanding the causes of corrosion, implementing effective removal methods, and adopting preventative measures, industries can significantly reduce the impact of corrosion and extend the lifespan of their assets. Choosing the right approach, from mechanical methods to chemical treatments and innovative laser cleaning, depends on the specific context and the type of material affected. Furthermore, a proactive approach to prevention, including the application of protective coatings and careful material selection, is paramount in minimizing the need for future corrosion removal. Regular inspections and adherence to best practices will ensure the continued integrity and safety of structures and equipment susceptible to corrosion. [See also: Industrial Maintenance Strategies] Therefore, investing in corrosion removal and prevention strategies is not just a cost-saving measure, but also a crucial step in ensuring safety and sustainability.