Blaster The Dry Lube with PTFE: A Comprehensive Guide

In the realm of lubricants, Blaster The Dry Lube with PTFE stands out as a versatile solution for a wide array of applications. This article delves into the properties, benefits, applications, and best practices associated with using this particular dry lubricant. Understanding its unique characteristics is crucial for maximizing its effectiveness and ensuring optimal performance in various mechanical systems.

Blaster The Dry Lube with PTFE is engineered to provide a clean, dry film lubrication that minimizes friction and wear. Unlike wet lubricants, it doesn’t attract dust, dirt, or grime, making it ideal for environments where cleanliness is paramount. The inclusion of Polytetrafluoroethylene (PTFE), commonly known as Teflon, further enhances its lubricating properties, offering exceptional resistance to heat, chemicals, and extreme pressure.

Understanding Dry Lubricants

Dry lubricants represent a distinct category of lubricants that, unlike their wet counterparts, leave behind a dry film on the surfaces they treat. This dry film reduces friction and wear without the sticky residue that can attract contaminants. The selection of a dry lubricant, such as Blaster The Dry Lube with PTFE, often hinges on the operating environment and the specific needs of the application. Dry lubricants are particularly advantageous in environments where cleanliness and resistance to contamination are critical.

Benefits of Dry Lubricants

- Reduced Friction: Dry lubricants create a thin, low-friction barrier between surfaces, minimizing wear and tear.

- Cleanliness: Because they don’t attract dirt and dust, dry lubricants keep mechanisms clean and functioning smoothly.

- Temperature Resistance: Many dry lubricants, including those with PTFE, can withstand high temperatures without breaking down.

- Chemical Resistance: PTFE offers excellent resistance to a wide range of chemicals, making it suitable for harsh environments.

- Long-Lasting: Dry lubricants often provide longer-lasting protection compared to wet lubricants, reducing the frequency of application.

What is PTFE and Why is it Important?

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a synthetic fluoropolymer of tetrafluoroethylene. Its exceptional properties include a low coefficient of friction, high chemical resistance, and excellent thermal stability. When incorporated into Blaster The Dry Lube with PTFE, PTFE significantly enhances its lubricating capabilities. PTFE’s low friction characteristics ensure smooth movement and reduce wear on treated surfaces. The chemical resistance of PTFE also makes the lubricant suitable for use in environments where exposure to harsh chemicals is a concern.

Key Properties of PTFE

- Low Coefficient of Friction: PTFE has one of the lowest coefficients of friction of any solid material, ensuring smooth movement and reduced wear.

- High Chemical Resistance: PTFE is resistant to a wide range of chemicals, including acids, bases, and solvents.

- Excellent Thermal Stability: PTFE can withstand high temperatures without degrading, making it suitable for high-temperature applications.

- Non-Stick Properties: PTFE’s non-stick nature prevents materials from adhering to treated surfaces.

Applications of Blaster The Dry Lube with PTFE

Blaster The Dry Lube with PTFE finds application in a diverse range of industries and scenarios. Its unique properties make it suitable for lubricating parts in environments where cleanliness, temperature resistance, and chemical resistance are paramount. Here are some common applications:

- Automotive: Use on door hinges, hood latches, trunk latches, and window tracks to reduce friction and prevent squeaks.

- Manufacturing: Lubricating moving parts in machinery to reduce wear and tear and ensure smooth operation.

- Aerospace: Applying to aircraft components where temperature extremes and chemical exposure are concerns.

- Firearms: Lubricating gun parts to ensure smooth cycling and prevent corrosion.

- Home and Garden: Use on door locks, hinges, garden tools, and sliding doors.

- Marine: Lubricating boat parts exposed to saltwater to prevent corrosion and reduce friction.

Specific Examples of Use

Consider a manufacturing plant that utilizes automated machinery. The consistent operation of these machines is crucial for maintaining production efficiency. Applying Blaster The Dry Lube with PTFE to the moving parts of these machines can significantly reduce friction and wear, leading to smoother operation and fewer breakdowns. This, in turn, translates to increased productivity and reduced maintenance costs. Similarly, in the automotive industry, applying the lubricant to door hinges and latches can eliminate squeaks and ensure smooth operation, enhancing the overall user experience. [See also: Automotive Lubricant Best Practices]

How to Apply Blaster The Dry Lube with PTFE

Proper application is key to maximizing the benefits of Blaster The Dry Lube with PTFE. Follow these steps for optimal results:

- Clean the Surface: Thoroughly clean the surface to be lubricated to remove any dirt, grease, or debris.

- Shake Well: Shake the can of Blaster The Dry Lube with PTFE well before use to ensure proper mixing of the components.

- Apply Sparingly: Apply a thin, even coat of the lubricant to the surface. Avoid over-application, as this can lead to buildup and reduced effectiveness.

- Allow to Dry: Allow the lubricant to dry completely before using the treated part or mechanism. This typically takes a few minutes.

- Reapply as Needed: Reapply the lubricant as needed to maintain optimal performance. The frequency of reapplication will depend on the specific application and operating conditions.

Tips for Effective Application

- Use in a Well-Ventilated Area: Ensure adequate ventilation when applying the lubricant to avoid inhaling fumes.

- Avoid Contact with Skin and Eyes: Wear gloves and eye protection to prevent contact with skin and eyes.

- Store Properly: Store the lubricant in a cool, dry place away from heat and open flames.

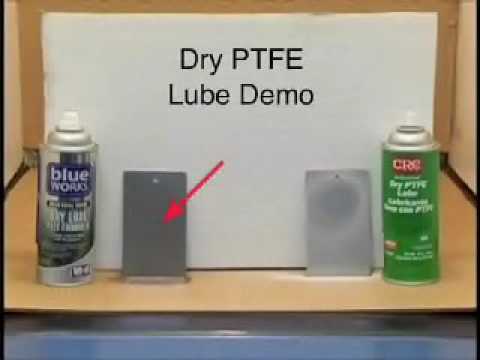

Comparing Blaster The Dry Lube with PTFE to Other Lubricants

When selecting a lubricant, it’s important to consider the specific requirements of the application. Blaster The Dry Lube with PTFE offers several advantages over other types of lubricants, including wet lubricants and other dry lubricants without PTFE. Wet lubricants, such as oil and grease, can attract dirt and dust, leading to increased wear and reduced performance. Dry lubricants without PTFE may not offer the same level of friction reduction and chemical resistance. [See also: Choosing the Right Lubricant]

Advantages of Blaster Dry Lube with PTFE

- Superior Cleanliness: Unlike wet lubricants, it doesn’t attract dirt or dust.

- Enhanced Lubrication: PTFE provides exceptional friction reduction and wear protection.

- Improved Chemical Resistance: PTFE offers excellent resistance to a wide range of chemicals.

- High-Temperature Stability: PTFE can withstand high temperatures without degrading.

Safety Precautions When Using Blaster The Dry Lube with PTFE

While Blaster The Dry Lube with PTFE is generally safe to use, it’s important to follow certain safety precautions to minimize the risk of injury or health problems:

- Ventilation: Use in a well-ventilated area to avoid inhaling fumes.

- Skin and Eye Protection: Wear gloves and eye protection to prevent contact with skin and eyes.

- Flammability: Keep away from heat, sparks, and open flames.

- Ingestion: Do not ingest. If swallowed, seek medical attention immediately.

- Storage: Store in a cool, dry place away from children and pets.

Troubleshooting Common Issues

Even with proper application, you may encounter some issues when using Blaster The Dry Lube with PTFE. Here are some common problems and their solutions:

- Lubricant Dries Too Quickly: Ensure the surface is clean and free of contaminants before applying. Apply a thinner coat of lubricant.

- Lubricant Doesn’t Reduce Friction: Ensure the lubricant is properly mixed before use. Reapply the lubricant as needed.

- Lubricant Attracts Dust: This is less likely with dry lubricants, but ensure the surface is clean before application. Consider using a different lubricant if cleanliness is a major concern.

Conclusion

Blaster The Dry Lube with PTFE is a highly effective lubricant for a wide range of applications. Its unique properties, including its dry film lubrication, PTFE enhancement, and resistance to heat and chemicals, make it an excellent choice for environments where cleanliness and performance are critical. By understanding its benefits, proper application techniques, and safety precautions, you can maximize its effectiveness and ensure optimal performance in your mechanical systems. Whether you’re lubricating automotive parts, machinery, or household items, Blaster The Dry Lube with PTFE offers a reliable and long-lasting solution for reducing friction and wear.