The Ultimate Guide to Frosted Acrylic Sheets: Properties, Applications, and Selection

In the world of materials science and design, frosted acrylic sheets stand out as a versatile and aesthetically pleasing option. These sheets, also known as translucent acrylic or satin acrylic, offer a unique combination of light diffusion, privacy, and durability, making them a popular choice for a wide range of applications. This comprehensive guide delves into the properties, applications, selection criteria, and advantages of using frosted acrylic sheets in your projects.

Understanding Frosted Acrylic Sheets

Frosted acrylic sheets are produced by either chemically etching or mechanically sanding the surface of a standard acrylic sheet. This process creates a textured surface that scatters light, resulting in a soft, diffused glow. Unlike clear acrylic, which is transparent, frosted acrylic offers a degree of privacy while still allowing light to pass through. The level of frosting can vary, affecting the amount of light transmission and the degree of obscurity.

Key Properties of Frosted Acrylic

- Light Diffusion: The primary characteristic of frosted acrylic sheets is their ability to diffuse light evenly, reducing glare and creating a softer, more pleasant illumination.

- Privacy: The frosted surface provides a level of privacy, making it suitable for applications where obscuring vision is desired.

- Durability: Acrylic is inherently strong and shatter-resistant, making frosted acrylic sheets a durable alternative to glass.

- Weather Resistance: Acrylic is resistant to UV radiation and weathering, making it suitable for both indoor and outdoor applications.

- Lightweight: Acrylic is significantly lighter than glass, making it easier to handle and install.

- Ease of Fabrication: Frosted acrylic sheets can be easily cut, drilled, and shaped using common tools.

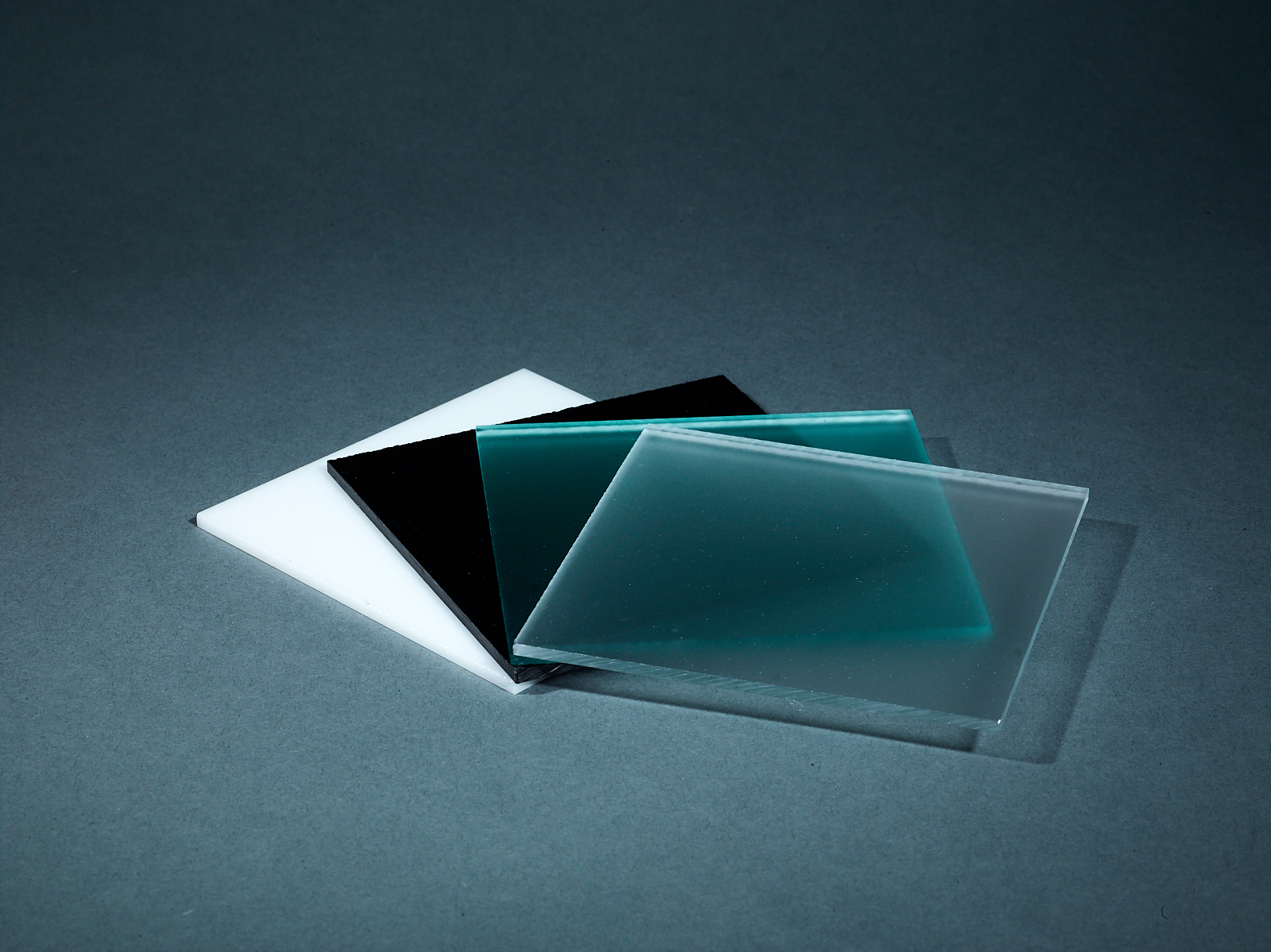

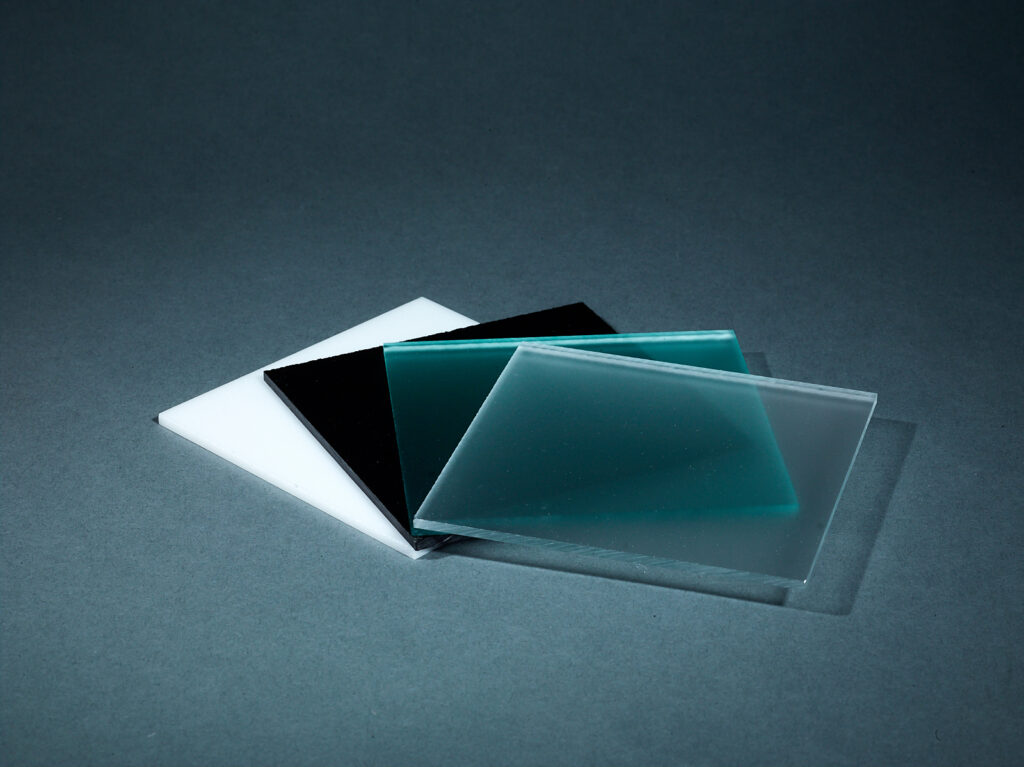

- Variety of Colors: While often available in clear or white, frosted acrylic can also be produced in a range of colors.

Applications of Frosted Acrylic Sheets

The unique properties of frosted acrylic sheets make them suitable for a diverse range of applications across various industries.

Architectural and Interior Design

In architecture and interior design, frosted acrylic is used for:

- Privacy Screens: Creating partitions in offices, restaurants, and other public spaces.

- Shower Doors and Enclosures: Providing privacy while allowing light to enter.

- Lighting Fixtures: Diffusing light in lamps, sconces, and ceiling fixtures.

- Signage: Creating illuminated signs with a soft, diffused glow.

- Backsplashes: Adding a touch of elegance and visual interest to kitchens and bathrooms.

- Wall Panels: Enhancing the aesthetic appeal of interior walls while offering durability.

Retail and Display

Retailers use frosted acrylic sheets for:

- Display Cases: Showcasing products while minimizing glare.

- Shelving: Creating visually appealing and durable shelving units.

- Point-of-Sale Displays: Highlighting products and promotions.

- Menu Boards: Providing a stylish and easy-to-read display for menus.

Signage and Advertising

The signage and advertising industries benefit from frosted acrylic’s ability to diffuse light, creating eye-catching displays:

- Backlit Signs: Producing illuminated signs with a soft, even glow.

- Dimensional Letters: Adding depth and visual interest to signage.

- Wayfinding Systems: Creating clear and easy-to-read directional signage.

Industrial Applications

Frosted acrylic also finds use in industrial settings:

- Machine Guards: Providing a safe and visible barrier around machinery.

- Laboratory Equipment: Constructing enclosures and components for laboratory equipment.

- Protective Covers: Shielding sensitive equipment from dust, debris, and moisture.

Selecting the Right Frosted Acrylic Sheet

Choosing the right frosted acrylic sheet for your project requires careful consideration of several factors.

Thickness

The thickness of the sheet should be determined by the application and the required structural integrity. Thicker sheets are generally more durable and less prone to bending or warping. Common thicknesses range from 1/8 inch to 1 inch or more.

Frost Level

The level of frosting affects the amount of light transmission and the degree of privacy. A higher level of frosting will result in a more diffused light and greater obscurity. Consider the specific requirements of your application when choosing the frost level. Samples are often available to help you visualize the effect.

Color

While clear frosted acrylic is the most common option, sheets are also available in a variety of colors. Consider the aesthetic requirements of your project when selecting a color. Colored frosted acrylic can add a unique touch and enhance the overall design.

Size

Frosted acrylic sheets are available in a range of standard sizes. Choose a size that minimizes waste and simplifies fabrication. Custom sizes may also be available from some suppliers.

Manufacturer and Quality

Opt for frosted acrylic sheets from reputable manufacturers known for producing high-quality materials. Look for sheets that are free from imperfections, such as scratches, bubbles, or discoloration. High-quality sheets will offer better light diffusion, durability, and overall performance.

Advantages of Using Frosted Acrylic Sheets

Compared to other materials, such as glass or standard acrylic, frosted acrylic sheets offer several distinct advantages:

- Enhanced Aesthetics: The frosted surface adds a touch of elegance and sophistication to any project.

- Improved Privacy: The translucent nature of frosted acrylic provides a degree of privacy without completely blocking light.

- Reduced Glare: The light-diffusing properties of frosted acrylic minimize glare, creating a more comfortable and visually appealing environment.

- Increased Safety: Acrylic is shatter-resistant, making frosted acrylic sheets a safer alternative to glass.

- Design Flexibility: Frosted acrylic can be easily cut, shaped, and fabricated to meet specific design requirements.

- Cost-Effectiveness: In many applications, frosted acrylic sheets offer a cost-effective alternative to other materials, such as etched glass.

Working with Frosted Acrylic Sheets

While frosted acrylic sheets are relatively easy to work with, it’s important to follow proper techniques to avoid damage or imperfections.

Cutting

Frosted acrylic can be cut using a variety of tools, including saws, routers, and laser cutters. When using a saw, use a fine-toothed blade designed for cutting plastics. When using a router, use a spiral upcut bit. Laser cutting provides the cleanest and most precise cuts.

Drilling

When drilling frosted acrylic, use a drill bit designed for plastics. Apply light pressure and avoid overheating the material. Back up the sheet with a piece of wood to prevent chipping.

Cleaning

Frosted acrylic sheets can be cleaned with a mild soap and water solution. Avoid using abrasive cleaners or solvents, as they can damage the frosted surface. Use a soft cloth or sponge to gently wipe the surface.

Protecting the Surface

During fabrication and installation, protect the frosted acrylic surface from scratches and damage. Use protective films or masking tape to cover the surface. Handle the sheets with care and avoid dragging them across rough surfaces. [See also: Acrylic Sheet Fabrication Techniques]

The Future of Frosted Acrylic Sheets

As technology advances, the applications and capabilities of frosted acrylic sheets continue to expand. New manufacturing processes are allowing for greater control over the level of frosting and the color options available. Innovations in lighting technology are also driving the demand for frosted acrylic in illuminated signage and displays. The future of frosted acrylic sheets is bright, with continued growth and innovation expected in the years to come. As designers and engineers seek versatile, aesthetically pleasing, and durable materials, frosted acrylic will undoubtedly remain a popular choice.

Conclusion

Frosted acrylic sheets offer a unique combination of light diffusion, privacy, and durability, making them a valuable material for a wide range of applications. Whether you’re designing architectural elements, creating retail displays, or developing industrial equipment, frosted acrylic provides a versatile and aesthetically pleasing solution. By understanding the properties, applications, and selection criteria outlined in this guide, you can make informed decisions and achieve optimal results in your projects. The enduring appeal of frosted acrylic sheets lies in their ability to blend functionality with visual appeal, making them a timeless choice for designers and engineers alike.