BNC Cables: Understanding Their Applications, Types, and Importance

In the world of electronics and signal transmission, the BNC cable stands as a crucial component. The term “BNC” stands for Bayonet Neill-Concelman, referring to the bayonet-style locking mechanism and the inventors, Paul Neill and Carl Concelman. This type of connector and cable assembly is widely used for connecting various electronic devices, particularly in radio, video, and test equipment. Understanding the nuances of BNC cables is essential for anyone working with these technologies. This article will delve into the applications, types, and importance of BNC cables, providing a comprehensive overview for both novices and seasoned professionals.

What are BNC Cables?

A BNC cable consists of a coaxial cable terminated with a BNC connector on one or both ends. The bayonet locking mechanism ensures a secure and reliable connection, which is particularly important in environments where vibrations or movement could disrupt the signal. The coaxial construction of the cable provides excellent shielding against electromagnetic interference (EMI), ensuring a clean and stable signal transmission. The BNC cable is a staple in many industries due to its robust design and consistent performance.

Applications of BNC Cables

BNC cables find applications in a wide array of fields, primarily due to their ability to transmit signals reliably and with minimal interference. Here are some key areas where BNC cables are commonly used:

Video Signals

One of the most prevalent uses of BNC cables is in transmitting video signals. They are commonly employed in professional video equipment, such as cameras, monitors, and video recorders. The superior shielding offered by BNC cables ensures high-quality video transmission, free from distortions or noise. In broadcast studios, security systems, and medical imaging, BNC cables are the go-to choice for ensuring clear and accurate video feeds.

Test and Measurement Equipment

BNC cables are indispensable in test and measurement environments. Oscilloscopes, signal generators, and spectrum analyzers often utilize BNC cables for connecting to circuits and devices under test. The reliable connection and shielding properties of BNC cables are crucial for obtaining accurate and repeatable measurements. Engineers and technicians rely on BNC cables to perform precise diagnostics and calibration tasks.

Radio Frequency (RF) Signals

In the realm of radio communication, BNC cables are used to transmit RF signals between various components, such as antennas, transmitters, and receivers. Their ability to maintain signal integrity over short distances makes them ideal for connecting RF equipment in laboratories and communication systems. While other connectors might be preferred for longer distances or higher frequencies, BNC cables offer a cost-effective and reliable solution for many RF applications.

Networking

Although less common in modern networking setups, BNC cables were historically used in early Ethernet networks. Thinnet Ethernet, also known as 10Base2, utilized BNC cables to connect computers in a linear bus topology. While Ethernet has largely transitioned to twisted pair cables and RJ45 connectors, some legacy systems may still rely on BNC cables for network connectivity.

Aerospace and Military Applications

The robustness and reliability of BNC cables make them suitable for use in aerospace and military applications. They can withstand harsh environmental conditions and provide secure connections for critical communication and instrumentation systems. In aircraft, satellites, and military vehicles, BNC cables play a vital role in ensuring the proper functioning of electronic equipment.

Types of BNC Cables

BNC cables come in various configurations to suit different applications and requirements. Understanding the different types of BNC cables is essential for selecting the right cable for a specific task.

Standard BNC Cables

These are the most common type of BNC cables, used for general-purpose signal transmission. They typically feature a male BNC connector on each end and are available in various lengths. Standard BNC cables are suitable for a wide range of applications, from video connections to test equipment setups.

Right-Angle BNC Cables

Right-angle BNC cables feature a BNC connector that is angled at 90 degrees. This design is useful in situations where space is limited or where a straight connector would put excessive strain on the cable. Right-angle BNC cables are often used in tight spaces behind equipment racks or in portable devices.

Panel-Mount BNC Connectors

Panel-mount BNC connectors are designed to be mounted on a panel or enclosure. They provide a convenient way to connect BNC cables to equipment without having to access the internal circuitry. Panel-mount BNC connectors are commonly used in test equipment, communication systems, and custom electronic devices.

T-BNC Connectors

T-BNC cables feature a T-shaped connector that allows for branching a signal. They are often used in test and measurement setups to split a signal between multiple devices. T-BNC cables can also be used to create a simple network topology, such as a bus network.

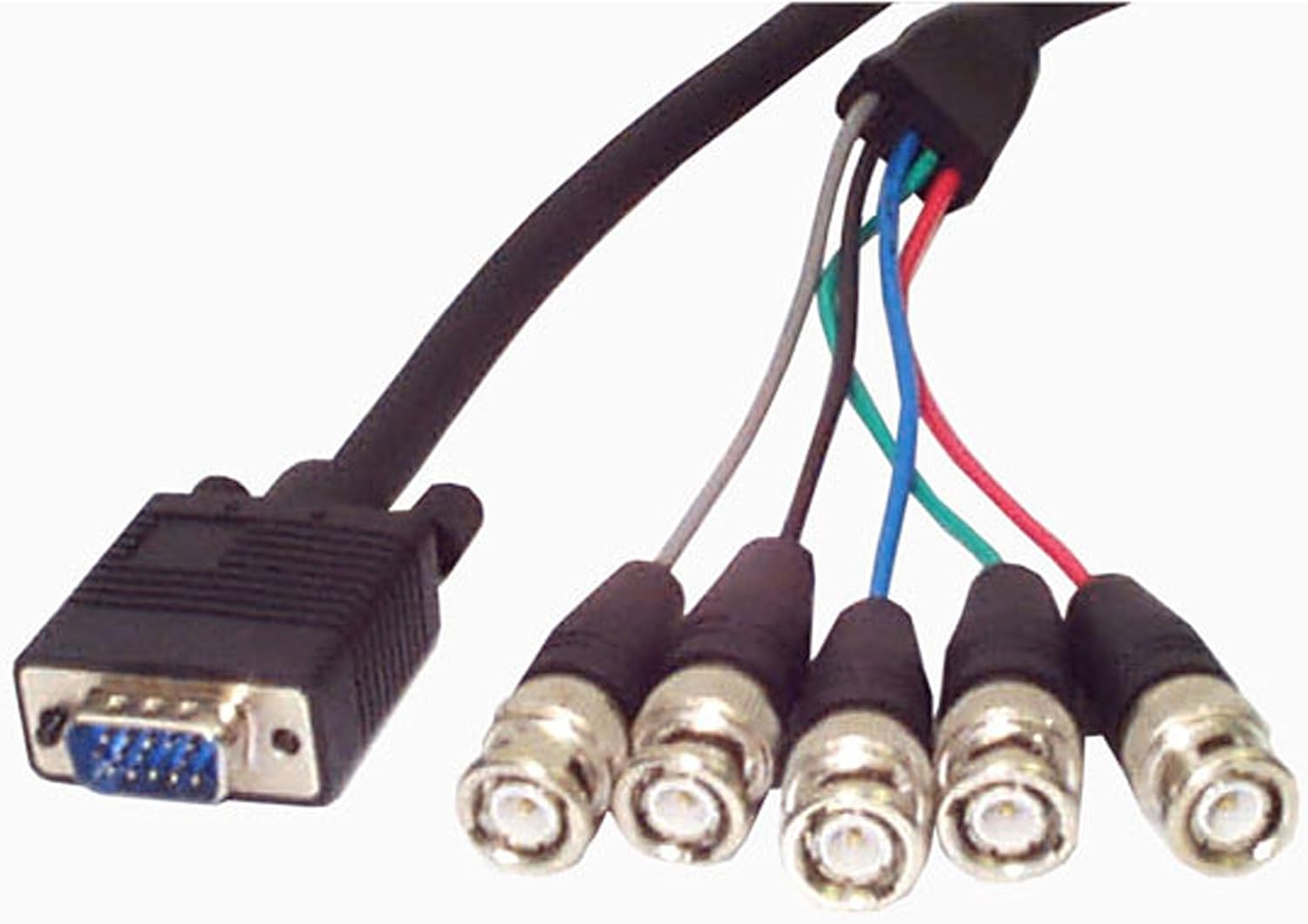

BNC to Other Connectors

BNC cables are also available with adapters to other types of connectors, such as RCA, SMA, or banana plugs. These adapters allow BNC cables to be used with a wider range of equipment that may not have BNC connectors. BNC cables with adapters are useful for connecting different types of devices in a mixed-signal environment.

Importance of Quality BNC Cables

The quality of a BNC cable can significantly impact the performance of electronic systems. A high-quality BNC cable ensures reliable signal transmission, minimal signal loss, and protection against interference. Conversely, a low-quality BNC cable can introduce noise, distortion, and signal degradation, leading to inaccurate measurements or unreliable communication. Here are some factors that contribute to the quality of BNC cables:

Shielding

Effective shielding is crucial for preventing electromagnetic interference from affecting the signal transmitted through the BNC cable. High-quality BNC cables utilize multiple layers of shielding, such as braided copper or foil, to block out external noise. The shielding should cover the entire length of the cable, including the connectors, to ensure maximum protection.

Connector Quality

The BNC connectors themselves should be made from high-quality materials and properly crimped or soldered to the cable. Poorly constructed connectors can introduce signal loss or create intermittent connections, leading to unreliable performance. The connectors should also be resistant to corrosion and wear to ensure long-term reliability.

Cable Construction

The coaxial cable used in the BNC cable should be constructed from high-quality materials, such as solid copper conductors and low-loss dielectric insulation. The cable should also be flexible enough to withstand bending and flexing without damage. A well-constructed cable ensures consistent signal transmission and minimizes signal loss.

Impedance Matching

BNC cables are typically designed to have a characteristic impedance of 50 ohms or 75 ohms. It is important to use BNC cables with the correct impedance for the application to minimize signal reflections and ensure optimal signal transmission. Mismatched impedance can lead to signal distortion and reduced performance. [See also: Understanding Impedance in Coaxial Cables]

Troubleshooting BNC Cable Issues

Even with high-quality BNC cables, issues can sometimes arise. Here are some common problems and how to troubleshoot them:

Signal Loss

If you experience a weak or distorted signal, the first step is to check the BNC cable for any signs of damage, such as cuts, kinks, or loose connectors. If the cable appears to be in good condition, try replacing it with a known working cable to see if the problem is resolved. Also, ensure that the impedance of the BNC cable matches the impedance of the equipment it is connected to.

Intermittent Connections

Intermittent connections can be caused by loose or corroded BNC connectors. Try tightening the connectors and cleaning them with a contact cleaner. If the problem persists, the connectors may need to be replaced. Ensure that the connectors are properly crimped or soldered to the cable to ensure a secure connection.

Noise and Interference

If you are experiencing excessive noise or interference, check the shielding of the BNC cable. Ensure that the shielding is intact and properly grounded. Also, try rerouting the BNC cable away from potential sources of interference, such as power cables or electronic equipment. Using a higher-quality BNC cable with better shielding can also help reduce noise and interference.

Conclusion

BNC cables are an essential component in many electronic systems, providing a reliable and secure connection for signal transmission. Understanding the different types of BNC cables, their applications, and the importance of quality is crucial for ensuring optimal performance. Whether you are working with video equipment, test instruments, or communication systems, choosing the right BNC cable can make a significant difference in the accuracy and reliability of your results. By following the guidelines outlined in this article, you can confidently select and troubleshoot BNC cables for your specific needs. The longevity and efficiency of electronic setups often hinge on the proper selection and maintenance of these seemingly simple, yet incredibly vital, components. So, next time you reach for a cable, remember the importance of the BNC cable and the role it plays in keeping the world connected.