Understanding the 6-48 Thread: A Comprehensive Guide

When dealing with precision instruments and specialized applications, understanding thread specifications is crucial. One such specification is the 6-48 thread. This article provides a comprehensive overview of what a 6-48 thread is, its characteristics, applications, and why it’s essential in various industries. We’ll delve into the specifics of this unique thread size and explore its significance in ensuring accuracy and reliability in the devices and equipment where it’s used.

What Exactly is a 6-48 Thread?

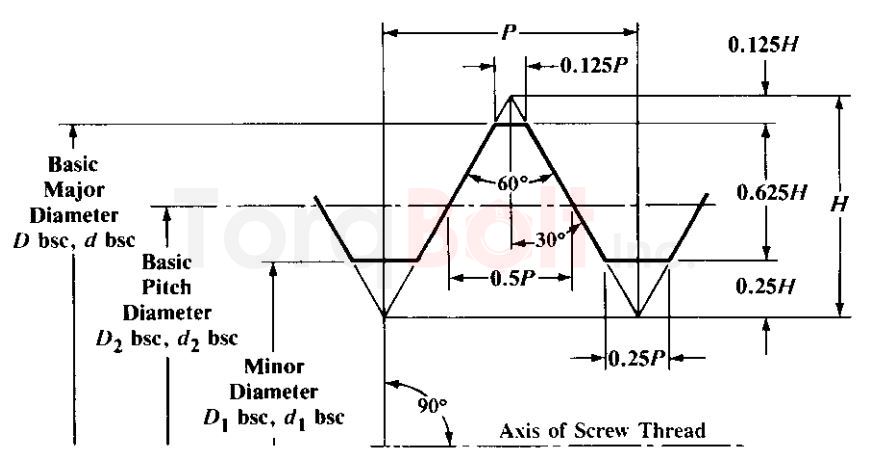

The term “6-48 thread” refers to a specific standardized screw thread size. In this designation, “6” indicates the nominal size of the screw, and “48” represents the number of threads per inch (TPI). This classification adheres to the Unified Thread Standard (UTS), widely used in the United States and other countries. Understanding each component of this designation is essential for proper application and procurement.

Breaking Down the Designation

- The ‘6’ Designation: The number 6 in the 6-48 thread specification refers to the nominal size of the screw. This number corresponds to a specific diameter, which, in this case, is approximately 0.138 inches.

- The ’48’ Designation: The number 48 indicates the threads per inch (TPI). This means there are 48 threads along one inch of the screw’s length. This high thread count signifies a fine thread, which is crucial for applications requiring precise adjustments and secure fastening.

Characteristics of the 6-48 Thread

The 6-48 thread possesses several key characteristics that make it suitable for specific applications. These characteristics include:

- Fine Thread: With 48 threads per inch, the 6-48 thread is considered a fine thread. Fine threads offer several advantages, including greater tensile strength for a given screw size and increased resistance to loosening under vibration.

- Precise Adjustments: The fine pitch allows for very small adjustments, making it ideal for applications where precision is paramount. This is particularly important in instruments and equipment that require accurate calibration.

- Strong Holding Power: The increased thread engagement of a fine thread provides a stronger hold compared to coarser threads. This is essential for ensuring the integrity and reliability of the assembled components.

- Smaller Size: A #6 screw is relatively small, making the 6-48 thread suitable for applications where space is limited. Despite its small size, it offers significant strength and precision.

Applications of the 6-48 Thread

The unique characteristics of the 6-48 thread make it ideal for a variety of applications across different industries. Here are some notable examples:

Firearms

One of the most common applications of the 6-48 thread is in the firearms industry. Specifically, it is frequently used for mounting scope bases to rifle receivers. The fine thread allows for precise alignment and secure attachment, ensuring that the scope remains accurately positioned even under recoil. The strength and precision offered by the 6-48 thread are crucial for maintaining the accuracy of the firearm.

Optical Instruments

Optical instruments such as microscopes, telescopes, and cameras often utilize the 6-48 thread. The need for extremely precise adjustments in these instruments makes the fine thread pitch invaluable. The 6-48 thread allows for minute adjustments of lenses and other optical components, ensuring optimal performance and image quality. The ability to make these fine adjustments is critical for achieving the desired level of accuracy and clarity.

Medical Devices

In the medical field, precision and reliability are non-negotiable. The 6-48 thread is used in various medical devices and equipment where accuracy is critical. Examples include surgical instruments, diagnostic equipment, and laboratory devices. The fine thread allows for precise control and secure fastening, contributing to the overall reliability and effectiveness of these devices. [See also: Medical Device Thread Standards]

Electronics

The electronics industry also benefits from the use of the 6-48 thread. It is often used in precision connectors, circuit board assemblies, and other electronic components. The small size and strong holding power of the 6-48 thread make it ideal for these applications. The fine thread pitch ensures secure connections and prevents loosening due to vibration, which is crucial for the reliable operation of electronic devices.

Aerospace

In the aerospace industry, components must withstand extreme conditions and maintain their integrity. The 6-48 thread is used in certain aerospace applications where precision and reliability are paramount. Examples include instrumentation, control systems, and small mechanical assemblies. The high tensile strength and resistance to loosening make the 6-48 thread a suitable choice for these demanding applications.

Advantages of Using the 6-48 Thread

There are several distinct advantages to using the 6-48 thread in appropriate applications:

- High Precision: The fine thread pitch allows for extremely precise adjustments, making it ideal for applications requiring accurate calibration and alignment.

- Strong Holding Power: The increased thread engagement provides a strong and secure hold, preventing loosening under vibration or stress.

- Compact Size: The small size of the #6 screw makes it suitable for applications where space is limited.

- Versatility: The 6-48 thread can be used in a variety of materials, including metals, plastics, and composites.

- Reliability: The robust design and strong holding power contribute to the overall reliability of the assembled components.

Disadvantages of Using the 6-48 Thread

While the 6-48 thread offers many advantages, it also has some limitations that should be considered:

- Susceptibility to Cross-Threading: The fine thread pitch makes it more susceptible to cross-threading if not properly aligned during installation.

- Lower Shear Strength: Compared to coarser threads of the same nominal size, the 6-48 thread may have lower shear strength.

- Increased Installation Time: The fine thread pitch requires more turns to achieve the same level of engagement, potentially increasing installation time.

- Potential for Galling: In certain materials, the fine thread pitch can increase the risk of galling if proper lubrication is not used.

Proper Installation Techniques

To ensure the optimal performance and longevity of components using the 6-48 thread, it is essential to follow proper installation techniques:

- Alignment: Ensure proper alignment of the screw and tapped hole to prevent cross-threading.

- Lubrication: Use appropriate lubrication to reduce friction and prevent galling, especially when working with stainless steel or other materials prone to seizing.

- Torque Control: Apply the correct torque to avoid over-tightening, which can damage the threads or the components being fastened.

- Thread Cleaning: Clean the threads of both the screw and the tapped hole to remove any debris or contaminants.

Alternatives to the 6-48 Thread

Depending on the specific application requirements, there may be alternative thread sizes that could be considered instead of the 6-48 thread. Some common alternatives include:

- 6-32 Thread: A coarser thread with 32 threads per inch. This may be suitable for applications where shear strength is more important than precise adjustment.

- 8-32 Thread: A larger screw size with 32 threads per inch. This offers increased strength and holding power compared to the #6 screw.

- Metric Threads: Metric threads, such as M3 or M3.5, may be used as alternatives, depending on the specific design requirements and available tooling.

Conclusion

The 6-48 thread is a specialized thread size that offers a unique combination of precision, strength, and compactness. Its fine thread pitch makes it ideal for applications requiring accurate adjustments and secure fastening. While it has some limitations, such as susceptibility to cross-threading and lower shear strength, these can be mitigated by following proper installation techniques. Understanding the characteristics, applications, advantages, and disadvantages of the 6-48 thread is essential for engineers, technicians, and anyone working with precision instruments and equipment. By carefully considering the specific requirements of the application, it is possible to determine whether the 6-48 thread is the right choice or whether an alternative thread size would be more suitable. The 6-48 thread continues to play a crucial role in ensuring the accuracy and reliability of numerous devices and equipment across various industries. [See also: Understanding Thread Pitch] Therefore, a thorough understanding of the 6-48 thread is invaluable for professionals seeking to optimize their designs and ensure the highest levels of performance.