Mastering Acrylic Molding: A Comprehensive Guide

Acrylic molding is a versatile manufacturing process used to create a wide range of products, from everyday household items to complex industrial components. Its popularity stems from acrylic’s inherent properties: transparency, durability, and ease of processing. This guide provides a comprehensive overview of acrylic molding, covering various techniques, applications, and best practices for achieving optimal results. Whether you’re a seasoned engineer or a curious hobbyist, understanding the nuances of molding acrylic is crucial for successful project execution.

Understanding Acrylic: Properties and Advantages

Before diving into the specifics of molding acrylic, it’s essential to understand the material itself. Acrylic, also known as polymethyl methacrylate (PMMA), is a thermoplastic polymer known for its exceptional clarity and resistance to ultraviolet (UV) light. Compared to glass, acrylic is lighter, more impact-resistant, and easier to work with. These properties make it an ideal material for various applications, including:

- Displays and Signage: Acrylic’s transparency and weather resistance make it perfect for creating eye-catching displays and durable signage.

- Automotive Components: Acrylic is used in tail lights, lenses, and interior trim due to its shatter resistance and ability to be molded into complex shapes.

- Medical Devices: Acrylic’s biocompatibility and sterilizability make it suitable for certain medical applications.

- Consumer Products: From furniture to kitchenware, acrylic’s aesthetic appeal and durability make it a popular choice for consumer goods.

The advantages of using acrylic in molding acrylic processes are numerous. It offers excellent optical clarity, allowing for the creation of transparent or translucent parts. Acrylic also exhibits good chemical resistance, making it suitable for use in environments where exposure to certain chemicals is unavoidable. Furthermore, acrylic is relatively easy to machine, bond, and decorate, providing designers with a high degree of flexibility.

Common Acrylic Molding Techniques

Several techniques are employed in molding acrylic, each with its own advantages and limitations. The choice of technique depends on factors such as part geometry, production volume, and budget. Here are some of the most common methods:

Injection Molding

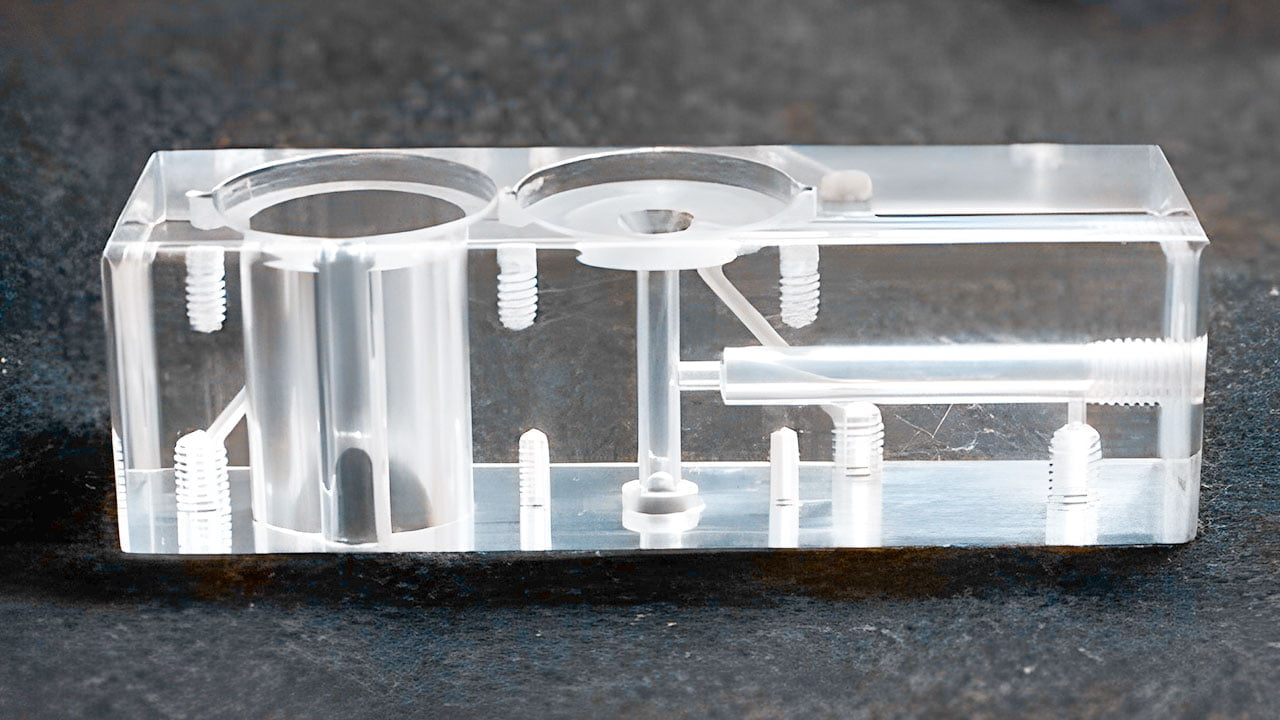

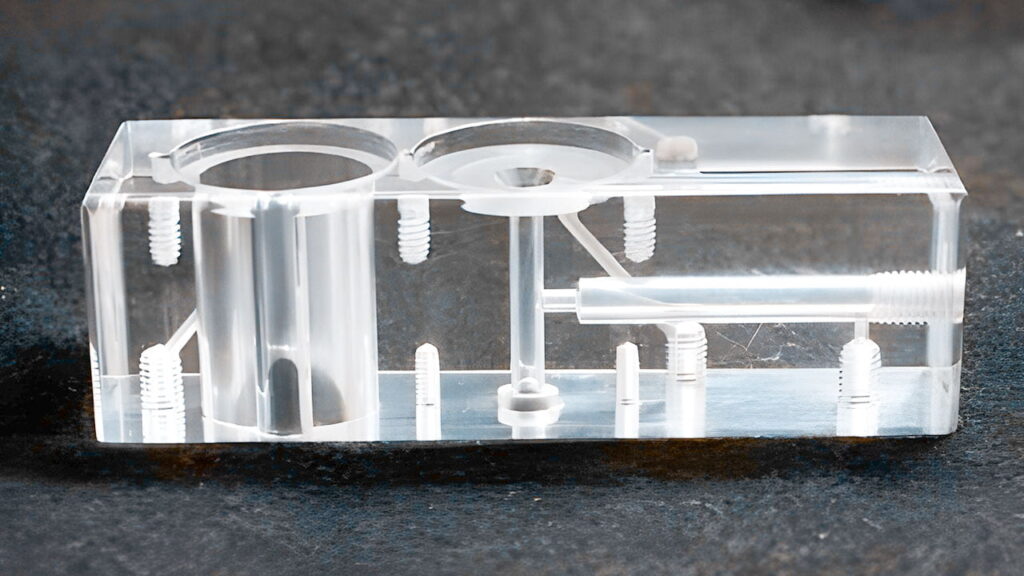

Injection molding is a widely used process for producing high volumes of acrylic parts. In this process, molten acrylic is injected into a mold cavity under high pressure. Once the acrylic cools and solidifies, the mold is opened, and the part is ejected. Injection molding is ideal for creating complex shapes with tight tolerances. The initial tooling cost can be high, but the cost per part decreases significantly with increasing production volume. Molding acrylic via injection molding allows for intricate designs and consistent replication.

Extrusion

Extrusion is a continuous process used to produce acrylic profiles with a constant cross-section. In this process, molten acrylic is forced through a die, shaping it into the desired profile. Extrusion is commonly used to produce acrylic sheets, rods, and tubes. It is a cost-effective method for producing long, uniform parts. The process of molding acrylic using extrusion is highly efficient for specific shapes.

Thermoforming

Thermoforming involves heating an acrylic sheet until it becomes pliable and then forming it over a mold using vacuum, pressure, or mechanical force. Thermoforming is suitable for producing large, shallow parts such as trays, covers, and enclosures. It is a relatively low-cost process compared to injection molding, making it ideal for prototyping and low-volume production. When molding acrylic with thermoforming, consider the uniform heating of the sheet for optimal results.

Compression Molding

Compression molding involves placing a preheated acrylic charge into a mold cavity and then applying pressure to force the material to fill the cavity. Compression molding is often used to produce large, flat parts with relatively simple geometries. It is a suitable method for producing parts with good surface finish and dimensional stability. The process of molding acrylic using compression can create strong and durable parts.

Designing for Acrylic Molding: Key Considerations

Successful molding acrylic requires careful consideration of design principles to ensure manufacturability and part performance. Here are some key design considerations:

- Draft Angles: Incorporate draft angles (typically 1-2 degrees) on vertical walls to facilitate part ejection from the mold.

- Wall Thickness: Maintain uniform wall thickness to prevent warping and ensure even cooling. Avoid sharp corners and transitions, as they can create stress concentrations.

- Ribs and Gussets: Use ribs and gussets to increase part stiffness and prevent deformation under load.

- Gate Location: Carefully consider the location of the gate (the point where the molten acrylic enters the mold cavity) to ensure proper material flow and minimize cosmetic defects.

- Shrinkage: Account for acrylic’s shrinkage rate during cooling to ensure that the final part dimensions meet specifications.

Troubleshooting Common Acrylic Molding Problems

Even with careful design and process control, problems can arise during molding acrylic. Here are some common issues and their potential solutions:

- Warping: Warping can occur due to uneven cooling or residual stress in the part. To prevent warping, ensure uniform wall thickness, use proper cooling techniques, and consider annealing the part after molding.

- Sink Marks: Sink marks are depressions on the surface of the part caused by localized shrinkage. They can be minimized by increasing wall thickness, optimizing gate location, and using appropriate molding parameters.

- Flow Lines: Flow lines are visible lines on the surface of the part caused by variations in material flow. They can be reduced by increasing melt temperature, optimizing gate location, and using a higher injection speed.

- Air Traps: Air traps are pockets of air trapped within the molded part. They can be prevented by venting the mold properly, optimizing gate location, and using a lower injection speed.

- Brittleness: Acrylic can become brittle if it is exposed to excessive heat or UV light. To prevent brittleness, use UV-stabilized acrylic grades and avoid prolonged exposure to high temperatures.

The Future of Acrylic Molding

The future of molding acrylic looks promising, with ongoing advancements in materials, processes, and technologies. New acrylic formulations are being developed with enhanced properties such as improved impact resistance, heat resistance, and chemical resistance. Additive manufacturing techniques, such as 3D printing, are also being used to create complex acrylic parts with intricate geometries. Furthermore, advancements in automation and process control are improving the efficiency and precision of acrylic molding operations.

Best Practices for Successful Acrylic Molding

To achieve optimal results in molding acrylic, consider the following best practices:

- Material Selection: Choose the appropriate acrylic grade for your application based on its specific requirements for clarity, impact resistance, heat resistance, and chemical resistance.

- Mold Design: Design the mold with proper draft angles, wall thickness, and gate location to ensure easy part ejection and minimize cosmetic defects.

- Process Control: Carefully control the molding parameters, such as melt temperature, injection pressure, cooling time, and mold temperature, to achieve consistent part quality.

- Quality Control: Implement a robust quality control system to detect and address any defects or inconsistencies in the molded parts.

- Post-Processing: Consider post-processing operations such as annealing, machining, bonding, and decorating to enhance the appearance and performance of the molded parts.

Specific Applications of Molded Acrylic

The versatility of molding acrylic lends itself to a vast range of applications across various industries. Here are a few specific examples:

- Point-of-Purchase (POP) Displays: Acrylic is frequently used for creating visually appealing and durable POP displays in retail environments. Its transparency allows for showcasing products effectively, while its resistance to damage ensures longevity.

- Lighting Fixtures: Acrylic’s excellent light transmission properties make it an ideal material for creating diffusers and lenses in lighting fixtures. It can be easily molded into various shapes and sizes to achieve desired lighting effects.

- Aquariums: Large-scale aquariums often utilize thick acrylic panels due to their superior strength and clarity compared to glass. Acrylic’s ability to withstand high water pressure makes it a safe and reliable choice.

- Protective Shields: In industrial settings, acrylic shields are used to protect workers from machinery hazards. Its impact resistance and transparency provide a safe and clear barrier.

- Custom Awards and Trophies: Acrylic’s aesthetic appeal and ability to be laser-engraved make it a popular material for creating custom awards and trophies.

In conclusion, molding acrylic is a powerful manufacturing process that offers a wide range of possibilities for creating high-quality, durable, and aesthetically pleasing products. By understanding the principles of acrylic molding, considering design best practices, and troubleshooting common problems, you can unlock the full potential of this versatile material. [See also: Acrylic Sheet Fabrication Techniques] [See also: Choosing the Right Acrylic Grade for Your Project]